Congratulations on your ASC Water Pump Purchase.

Firstly, the staff at ASC Water Tanks would like to thank you whole heartedly for your new water pump purchase. Your purchase supports local jobs in the industry and we thank you for choosing to support local.

ASC Water Pumps have been made to the highest standard, and we take great pride in the quality of our water pumps. We have over 15 years of experience in the industry and wanted to develop and manufacture a high quality Water Pump that would give you trouble free, reliable operation for years to come.

This guide has been put together for customers of ASC Water Tanks to setup their pump correctly and safely to ensure you get the best performance and lifetime from your new water pump.

ASC offers a standard two year warranty across our entire ASC Water Pumps range. Optional warranty for surface mounted pumps can be added at the time of purchase of your water pump. The extended warranty does not cover the following:

– Wearing parts including all seals and motor bearings

– Capacitor

– Pumps that are not covered or protected from the environment

– Power surges that damage the motor through fusion or short circuit the pump controller.

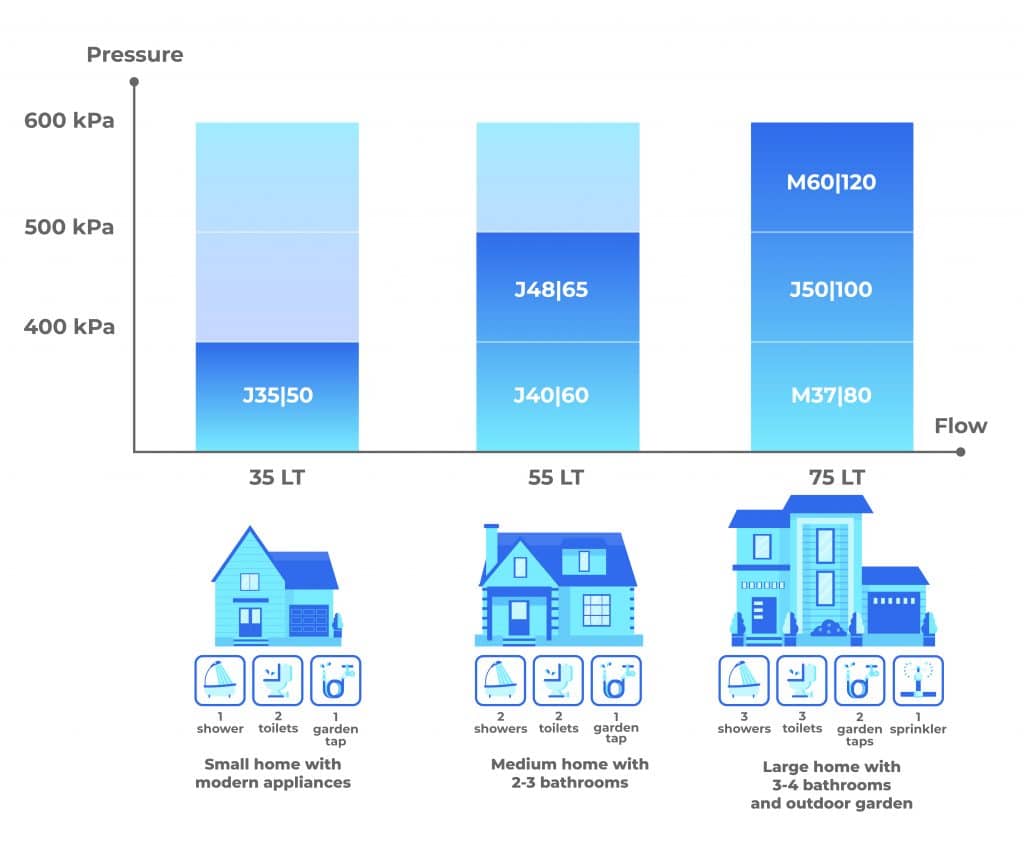

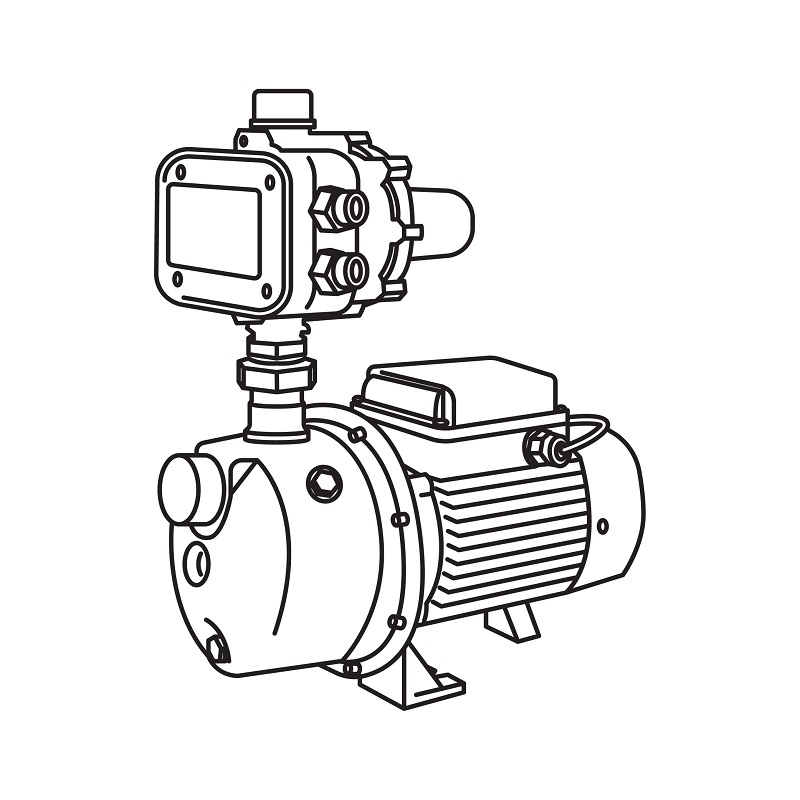

ASC Water Tanks offers three ranges of Water Pumps. A Jet pump range, a horizontal multistage range and submersible pumps. Each style and type of pump offers various advantages and disadvantages.

For warranty terms and conditions on ASC grinder series pumps, including the ASC GC-07A and ASC DSK-10A, please click here.

JET Pump Installation Guide

ASC JET Pumps Installation & Operating Instructions

Suitable for the following pumps: ASC J35/50, ASC J40/60, ASC J48/65, ASC J50/100.

WARNING: Please read the following carefully and follow the instructions and comply with all applicable electrical and plumbing codes. Failure to do so may result in serious bodily injury and/or property damage.

Cautions:

- Protect the pump and controller from rain and moisture and minimise exposure to extreme heat and cold. Operating range from 2° – 40°.

- The pump is designed for use with clean water. Contamination including sand or mineral deposits may affect the operation of the pump and controller.

- The pH of the water must be between 6.5 and 8.5.

- The pump is not suitable for use with spa or pool water.

- Running the pump without water or allowing the pump to run dry will damage the mechanical seal and void the warranty.

- Avoid situations where the pump could be exposed to corrosive liquids or gasses, or flammable materials, solvents etc.

- Fitment and replacement must be carried out by competent, skilled and qualified personnel.

- In the event of leaking, ensure the enclosure has adequate drainage.

- All transport plugs are removed from the pump.

- The pump is primed correctly prior to turning the pump on.

- All pipework is correctly sealed, the correct size pipework is connected and supported.

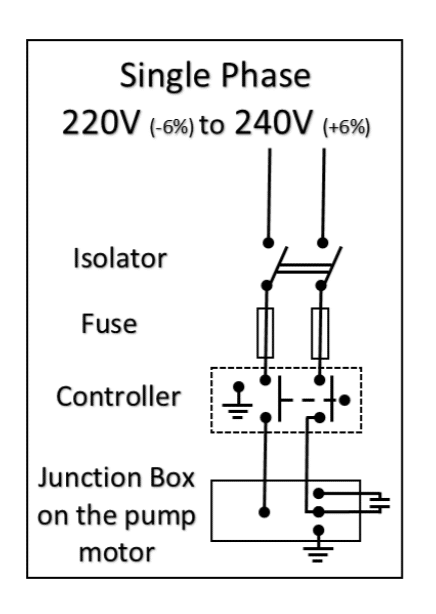

Electrical Connections

Always use an electrical outlet that is protected by a Residual Current Device (RCD) Safety Switch with a trip current of 30mA or less. A safety switch is required by Australian / New Zealand Standard AU/NZS 60335.1-2011.

Your new ASC JET Pump is supplied with a 1.5 meter, 10 amp rated lead and AS/NZS 3112 (Type I) 3 pin male power plug for connecting to mains power.

Exercise care with the power cord. Do not cut the power cable or use a pump that has a damaged power cord. Never lift the pump by the power cord or disconnect from the power supply by pulling the cord.

Cautions for Installation

Try to install your water pump as close to your water source as possible. Find a location with a firm base and close to your power supply. It is important to avoid extension cords. If you must use an extension cord, ensure that it is correctly rated. Under rated extension cords will have a large voltage drop which will damage your pump motor.

The pump must be installed in a weather proof location or otherwise under a pump cover. This helps protect your pump from rain which will prematurely damage your pump and is not covered by warranty. Ensure your pump installation location has free drainage in case of leakage, and is in a well ventilated area to protect it from extreme Australian temperatures, flooding, vermin and insects.

We have taken every measure to ensure your pump arrives safely and in perfect condition. We use recyclable materials in packaging your water pump and we hope that our great couriers network deliver your parcel safely. That said, we ask you to inspect the pump prior to installation to check for any damage from shipping.

We recommend flexible fittings for your water pump installation. This allows for some flexibility between your water tank and pump and reduces the stress on your fittings.

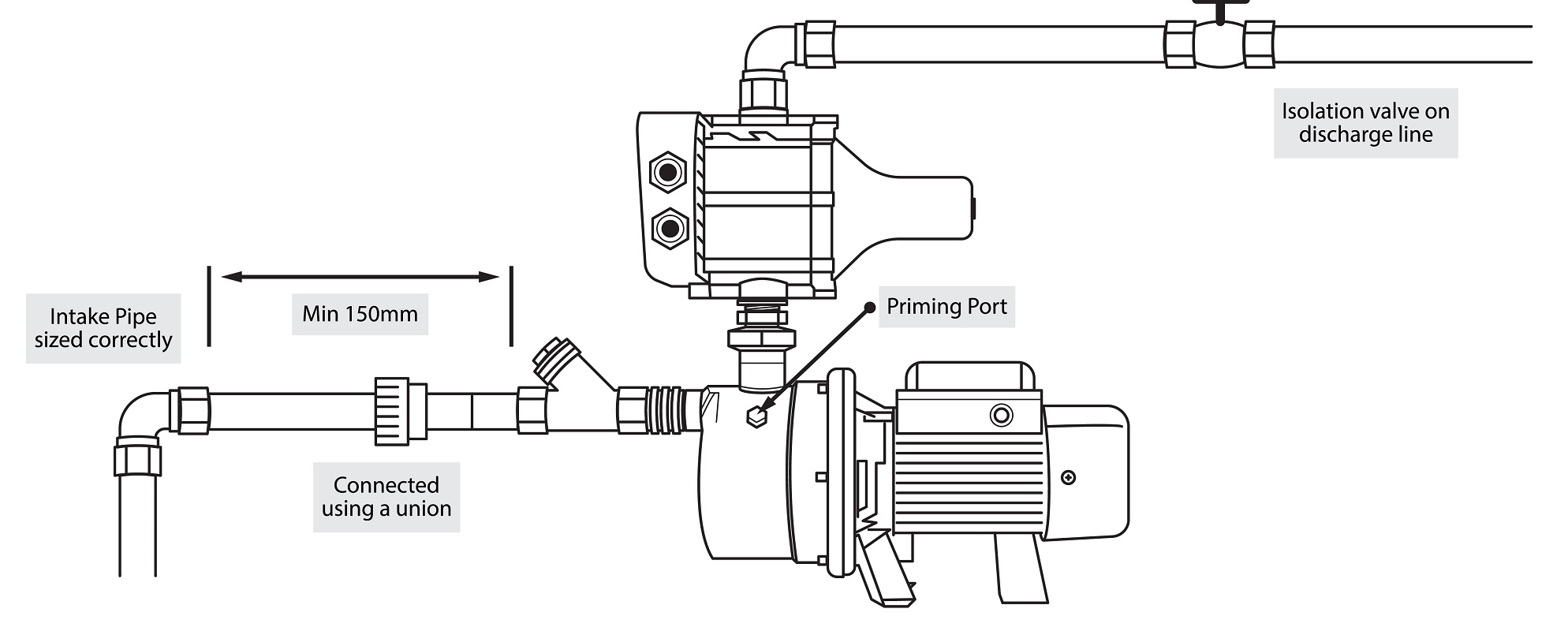

Connecting your Pump Inlet (Suction side)

Correct installation of your water pump is critical to make sure your pump runs smoothly and reliably. The inlet connection is one of the most critical parts of your installation. Here are some important factors for best practice when installing your suction pipe:

- Your inlet pipework size must be the equal to or larger than the pump inlet.

- Keep your inlet pipework as straight as possible and avoid 90° bends. This restricts flow considerably and drops your pump performance. We recommend flexible pipework that allows soft bends in the your pipework.

- Avoid bends within 150mm of your pump inlet.

- Install a barrel union on your pump inlet pipework for easy removal and pump servicing.

- Install a Y-Strainer on your pump inlet to protect your pump from debris damaging your pump.

- Make sure all your fittings use Teflon tape and create an airtight seal to prevent air entering your system.

- If your JET water pump is being installed above your water source, you must fit a non return valve on the end of the suction pipework.

NOTE: Leaks on your suction end are the largest cause of poor pump performance and also the most difficult to detect. Use thread tape on fittings and make sure isolation valves are installed between water tanks and pumps for both maintenance and testing.

Pump Priming & Operation

Pump Priming & Operation

Our range of ASC JET pumps are self priming water pumps, however on installation does need to be manually primed. That is, we need to bleed all the air that is inside the pump housing and displace it with water. Priming the pump also helps to lubricate your mechanical seal. Without priming your pump prior to turning your water pump on will cause irreparable damage to the mechanical seal and is not covered under warranty.

How to Prime you Water Pump?

- Ensure the pump power supply is disconnected.

- Turn the valve off between your water tank and water pump.

- Unscrew your pump priming port bolt.

- Fill the pump body and suction line completely with clean water via priming port. Alternatively, if your water tank is above ground, you can slowly open the valve between your water tank and pump. This will start pushing water through the lines and fill your pump body. When the pump body is full, turn the valve off.

- Screw your pump priming port and ensure it’s tight.

- Open the valve between your water tank and pump.

- Check all your inlet fittings and pipework to make sure there are no leaks.

- Turn your water pump on at the power supply with a tap open.

- Once the pump is running smoothly with good flow, turn the tap off. The pump should turn off once the line has pressurized.

Horizontal Multistage Pump Installation Guide

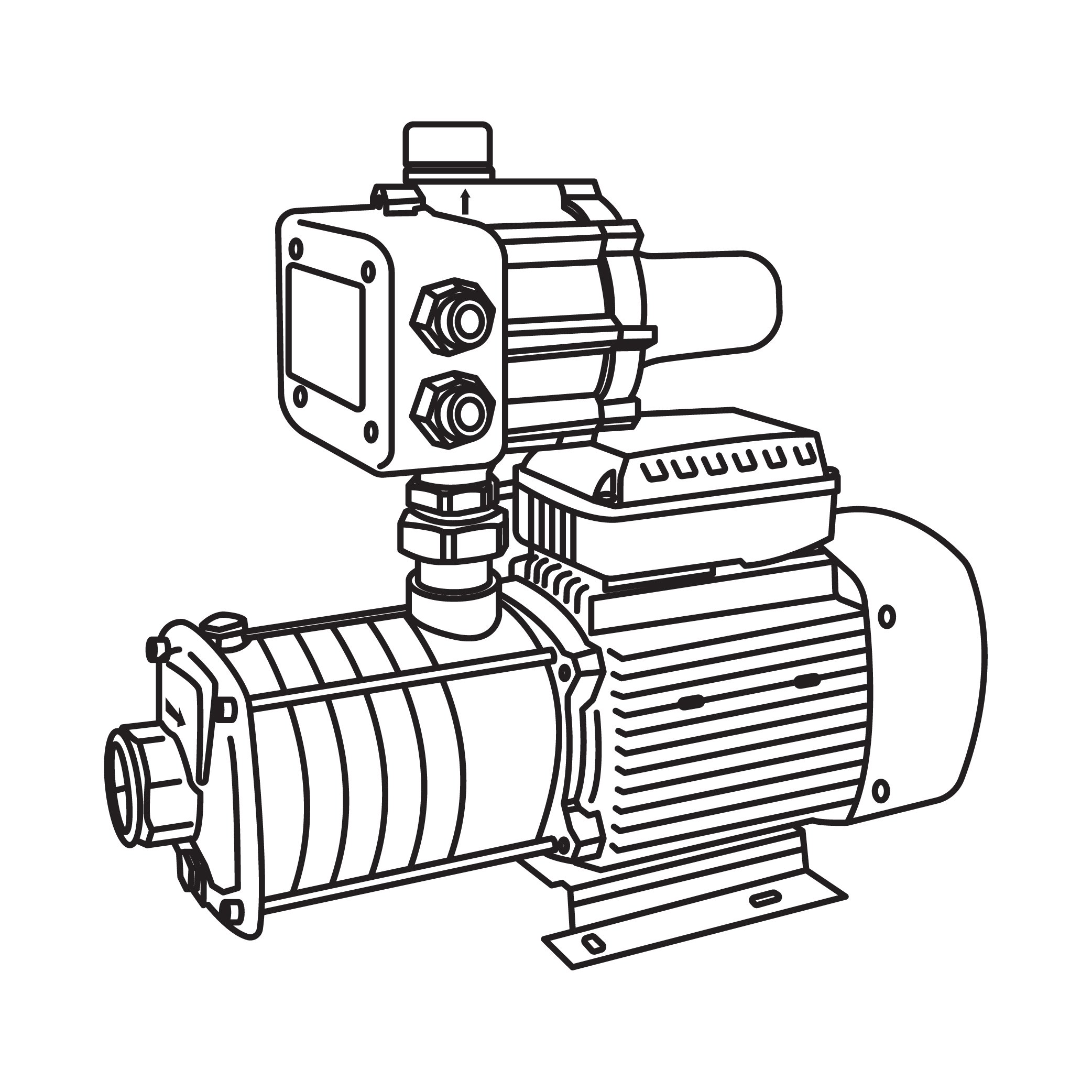

ASC Multistage Pumps Installation & Operating Instructions

Suitable for the following pumps: ASC M38/50, ASC M37/80, ASC M55/85, ASC M60/120.

WARNING: Please read the following carefully and follow the instructions and comply with all applicable electrical and plumbing codes. Failure to do so may result in serious bodily injury and/or property damage.

Cautions:

- Protect the pump and controller from rain and moisture and minimise exposure to extreme heat and cold. Operating range from 2° – 40°.

- The pump is designed for use with clean water. Contamination including sand or mineral deposits may affect the operation of the pump and controller.

- The pH of the water must be between 6.5 and 8.5.

- The pump is not suitable for use with spa or pool water.

- Running the pump without water or allowing the pump to run dry will damage the mechanical seal and void the warranty.

- Avoid situations where the pump could be exposed to corrosive liquids or gasses, or flammable materials, solvents etc.

- Fitment and replacement must be carried out by competent, skilled and qualified personnel.

- In the event of leaking, ensure the enclosure has adequate drainage.

- All transport plugs are removed from the pump.

- The pump is primed correctly prior to turning the pump on.

- All pipework is correctly sealed, the correct size pipework is connected and supported.

Electrical Connections

Always use an electrical outlet that is protected by a Residual Current Device (RCD) Safety Switch with a trip current of 30mA or less. A safety switch is required by Australian / New Zealand Standard AU/NZS 60335.1-2011.

Your new ASC Multistage Pump is supplied with a 1.5 meter, 10 amp rated lead and AS/NZS 3112 (Type I) 3 pin male power plug for connecting to mains power.

Exercise care with the power cord. Do not cut the power cable or use a pump that has a damaged power cord. Never lift the pump by the power cord or disconnect from the power supply by pulling the cord. Cutting the power cable voids your warranty.

Cautions for Installation

It is advisable that installation be carried out by skilled personnel having the technical qualifications and understanding of the relevant electrical legislation. Skilled personnel refers to persons who have been authorised by the person in charge of the plant safety who able to recognise and avoid all dangers as a result of their training, experience and instruction and their knowledge of the relevant standards and regulations (IEC364)

Try to install your water pump as close to your water source as possible. Find a location with a firm base and close to your power supply. It is important to avoid extension cords. If you must use an extension cord, ensure that it is correctly rated. Under rated extension cords will have a large voltage drop which will damage your pump motor.

The pump must be installed in a weather proof location or otherwise under a pump cover. This helps protect your pump from rain which will prematurely damage your pump and is not covered by warranty. Ensure your pump installation location has free drainage in case of leakage, and is in a well ventilated area to protect it from extreme Australian temperatures, flooding, vermin and insects.

We have taken every measure to ensure your pump arrives safely and in perfect condition. We use recyclable materials in packaging your water pump and we hope that our great couriers network deliver your parcel safely. That said, we ask you to inspect the pump prior to installation to check for any damage from shipping.

We recommend flexible fittings for your water pump installation. This allows for some flexibility between your water tank and pump and reduces the stress on your fittings.

Connecting your Pump Inlet (Suction side)

Correct installation of your water pump is critical to make sure your pump runs smoothly and reliably. The inlet connection is one of the most critical parts of your installation. Here are some important factors for best practice when installing your suction pipe:

- Your inlet pipework size must be the equal to or larger than the pump inlet.

- Keep your inlet pipework as straight as possible and avoid 90° bends. This restricts flow considerably and drops your pump performance. We recommend flexible pipework that allows soft bends in the your pipework.

- Avoid bends within 150mm of your pump inlet.

- Install a barrel union on your pump inlet pipework for easy removal and pump servicing.

- Install a Y-Strainer on your pump inlet to protect your pump from debris damaging your pump.

- Make sure all your fittings use Teflon tape and create an airtight seal to prevent air entering your system.

- Multistage Pumps cannot be used for suction lift applications. You must have a flooded suction system to ensure the pump will work.

NOTE: Leaks on your suction end are the largest cause of poor pump performance and also the most difficult to detect. Use thread tape on fittings and make sure isolation valves are installed between water tanks and pumps for both maintenance and testing.

How to Prime you Water Pump?

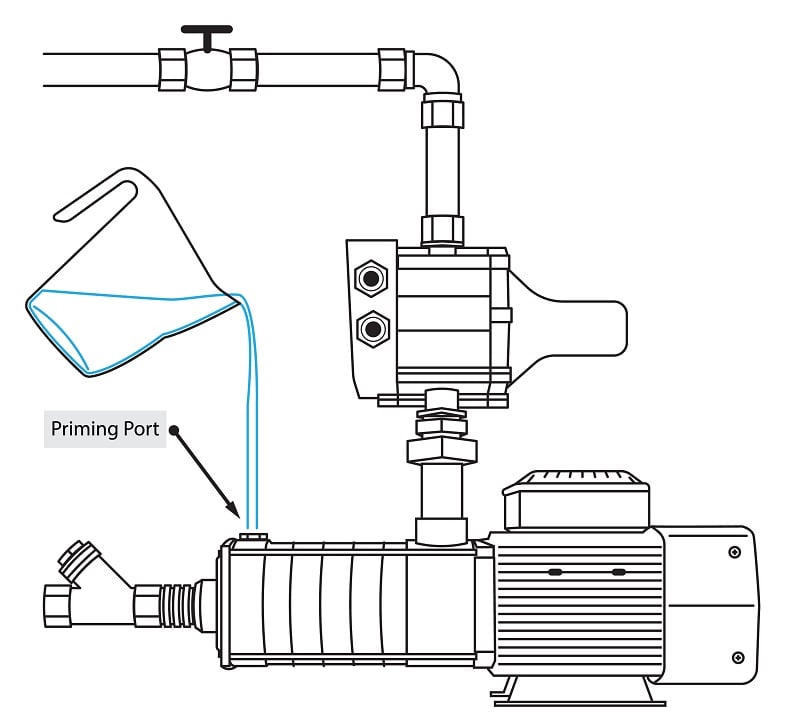

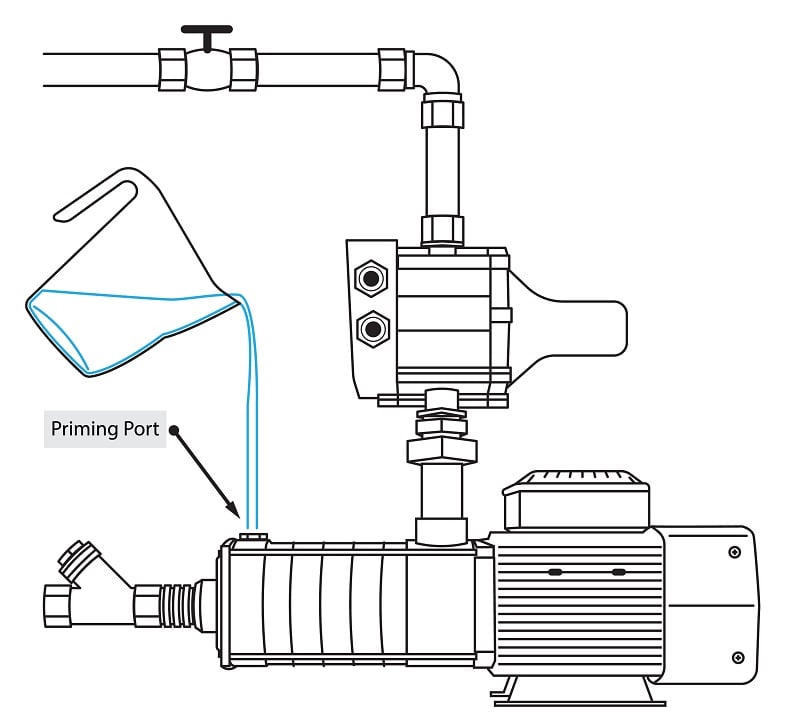

- Ensure the pump power supply is disconnected.

- Turn the valve off between your water tank and water pump.

- Unscrew your pump priming port bolt.

- Fill the pump body and suction line completely with clean water via priming port. Alternatively, if your water tank is above ground, you can slowly open the valve between your water tank and pump. This will start pushing water through the lines and fill your pump body. When the pump body is full, turn the valve off.

- Screw your pump priming port and ensure it’s tight.

- Open the valve between your water tank and pump.

- Check all your inlet fittings and pipework to make sure there are no leaks.

- Turn your water pump on at the power supply with a tap open.

- Once the pump is running smoothly with good flow, turn the tap off. The pump should turn off once the line has pressurized.

ASC Domestic Surface Mounted Pump Warranty

This warranty is given in addition to the consumer guarantees found within the Australian Competition and Consumer Act 2010 (Cth) for goods purchased in Australia.

ASC Water Tanks (ASC) warrants your domestic surface mounted water pump to be free of defects in material and workmanship for a minimum period of two (2) years from the date of original purchase as stated on the invoice. Standard wear and tear and fit for purpose conditions apply and adequate servicing of your pump over its lifetime. Subject to the conditions of the warranty, ASC will repair or replace any defective products free of charge at the premises of our authorized service centre or during the warranty period.

Your warranty does not cover:

- neglect, misuse, negligence, damage or accident

- any alterations made to the products or modifications to the pump

- any attempted repairs made to your pump unless instructed by ASC and it’s Agents

- damage caused by incorrect installation or not installed in accordance with ASC guidelines

- abnormal conditions such as incorrect voltage supply, lightning or high voltage spikes, or damages from electrolytic action, cavitation, sand, corrosive, saline or abrasive liquids,

If you believe that you have purchased a defective product and wish to make a claim under this warranty, contact ASC on (03) 8795 7715 or send your claim to our postal address and we will advise you as to how next to proceed. You will be required to supply a copy of your proof of purchase to make a claim under this warranty.

This warranty excludes transportation costs to ASC. If the returned product has failed due to material or workmanship, ASC will cover the cost of returning your goods at our expense. If you make an invalid claim under this warranty, the original product will be sent back to you unrepaired at your cost.

This warranty refers only to products sold after the 1st January 2020, and is not transferable to another product type and only applies to the original owner, purchaser or end user, and is in addition to the consumer guarantees found within the Competition and Consumer Act 2010 (Cth) for goods purchased in Australia.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure. We do not cover the costs of plumbing to remove or re-install your pump. You are also entitled to have the goods repaired or replaced (at ASC’s discretion) if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

To the fullest extent permitted by law, ASC excludes its liability for all other conditions or warranties which would or might otherwise be implied at law. To the fullest extent permitted by law, ASC’s liability under this warranty and any other conditions, guarantees or warranties at law that cannot be excluded, including those in the Competition and Consumer Act 2010 (Cth), is expressly limited to in the case of products, the replacement of the product or the supply of equivalent product, the payment of the cost of replacing the product or of acquiring an equivalent product or the repair of the product or payment of the cost of having the product repaired, is at the discretion of ASC or a 3rd party tribunal elected under the Competition and Consumer Act 2010 (Cth) for goods purchased in Australia.

Products presented for repair may be replaced by refurbished products of the same type rather than being repaired. Refurbished parts may be used to repair the products.

To the fullest extent permitted by law or statute, ASC shall not be liable for any loss of profits or any consequential, indirect or special loss, damage or injury of any kind whatsoever arising directly or indirectly from ASC products. This limitation does not apply to any liability of ASC for failure to comply with a consumer guarantee applicable to your ASC product under local laws and does not affect any rights or remedies that may be available to you under local laws.

Trouble Shooting Guide

ASC Water Tanks is committed to the long term service of your water pump. We have experts who are here to help you select the right pump and guide you through any issues you may encounter after your water pump purchase. We kindly ask that you read through the following trouble shooting guide to help you diagnose and hopefully resolve the issue. After 15 years of experience in the industry we are fairly confident that most of your issues can be fixed by following the instructions provided in this guide.

The pump is not starting I can’t hear hear anything.

Possible Cause: No Electricity | Potential Solution: Check the power supply. Is the Power LED on the controller illuminated? Check if another powered device works on the same power point.

Possible Cause: Fuses or RCD tripped | Potential Solution: Fuses or RCD tripped may indicate more serious problems. Speak to your electrician or contact ASC.

Possible Cause: The static head pressure is greater than the pump cut in pressure. | Potential Solution: Static water head above the controller must be less than 20m.

Possible Cause: Controller has sensed dry run and is in an auto-restart cycle. | Potential Solution: Press the reset button on your pump controller.

The pump doesn’t start but makes a noise.

Possible Cause: Motor not free to turn. Debris has caused internal jamming of the impeller. | Potential Solution: Pump needs to be inspected by an Authorized pump expert to remove debris.

Possible Cause: Faulty Capacitor. | Potential Solution: Contact an expert to check/replace your capacitor. Capacitors have a limited life span. Some factors such as rapid cycling cause your capacitors to fail prematurely. This is not covered under warranty.

The pump runs but there is no flow or only poor flow.

Possible Cause: Valves closed. | Potential Solution: Check your suction and discharge isolating valves and make sure they are open.

Possible Cause: Air entering suction line (loss of prime). | Potential Solution: Check for leaks on your suction end and make sure all fittings are sealed.

Possible Cause: Water level is low. | Potential Solution: Check your water source to ensure adequate water available.

Possible Cause: Y-Strainer or inlet filter is blocked. | Potential Solution: If you have a filter installed on your suction end and/or discharge end, make sure you have cleaned them or replaced them to allow water to flow through.

Possible Cause: Blockages in the pump, suction or discharge line. | Potential Solution: Contact ASC or a local pump service agent to remove blockages.

The Pump is cycling on and off.

Possible Cause: Small water draw off or leak. | Potential Solution: Check for small leaks. Normally these can occur on your taps or toilet cisterns. Close the valve on the outlet of your water pump, and see if the issue still occurs. If not, the issue is downstream of the pump. Contact a plumber.

Possible Cause: Leak in suction line. | Potential Solution: Check for leaks between the suction line and non return valve.

Pump runs intermittently

Possible Cause: Overheating and thermal protection tripping. | Potential Solution: Ensure the water temperature is less than 40°C and that there is sufficient air flow over the motor.

Possible Cause: Insufficient Power Supply. | Potential Solution: Low voltage power supply can cause the motor to overheat. Contact your electrician.

Pump vibrates and/or is very noisy

Possible Cause: Internal blockage causing impeller imbalance. | Potential Solution: Contact ASC or a local pump service agent to remove blockages.

Possible Cause: If the flow requirement is greater than the pump is capable of it will cavitate. Cavitation sounds like gravel inside your pump. | Potential Solution: Reduce the water demand to see if the noise drops away. Ensure your suction side inlet pipe matches your pump inlet fitting.

Possible Cause: Pump body has air in it. | Potential Solution: Re-prime your water pump to remove any air in the system.

Water leaking from the centre of the pump.

Possible Cause: The mechanical seal is leaking. | Potential Solution: Contact ASC or a local pump service agent for inspection. The mechanical seal is a wearing part and like your car tyres wears over time. This is not a warrantable part.