Davey Firefighter Engine Driven Pump 5150HD

SKU: 5150HD

APPLICATION

Ideal for domestic outdoor firefighting, occasional water transfer, sheep jetting and emergency irrigation.

FEATURES & BENEFITS

• Driven by a Honda GP160 engine which is specially designed for domestic or infrequent use

• Patented clamped impeller design to enable longer impeller life, improved performance and easier disassembly in the case of blockage.

• Thrust balanced impeller design to extend engine life.

• Pump casing, diffusers and impellers manufactured from quality corrosion resistant marine grade aluminium for long life.

• 3 way discharge port for easy installation with a choice of plumbing sizes.

• Patented floating impeller neck-rings front and back. The front neck-ring helps improve pumping efficiency, the back neck-ring helps extend seal life and dramatically reduce engine wear.

• Self priming from 7m for more versatile installation options.

• Large priming and drain port with bayonet fit plugs. Plugs have safety retention system, plus are available with 1/4″ tapping to accept pressure gauges or drain cocks.

• The new GP160 is based on the proven design of its heavy duty brother, the GX160. The difference is in the modification of some components to better suit the less arduous requirements of the normal home owner where annual usage may be no more than 150 hours.

• Where your application requires frequent and long hours of usage Davey recommend the extensive range of Davey 5 Series Firefighter pumps equipped with Honda GX series engines. Honda GP160 engines conform to the environmental requirements of the European EPA standards, to help look after the environment.

SPECIFICATIONS:

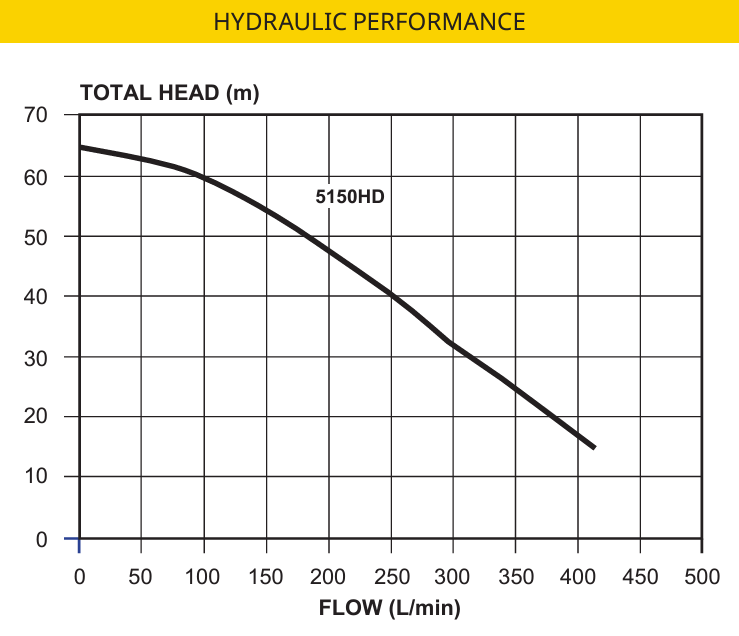

- Flow capacities to: 500 lpm

- Maximum total head: 60m

- Maximum suction lift: 7m

- Maximum water temperature: 50ºC

- Minimum water temperature: 1ºC

- Maximum casing pressure: 1000kPa

- Minimum suction pipe size: 1 ½”

- Suction pipe strainer: Required

- Inlet size*: 1 ½” or 2”

- Outlet sizes*: (4 Way)

- 2 x 1 ½” BSP(M)

- 2 x 1” BSP(M)

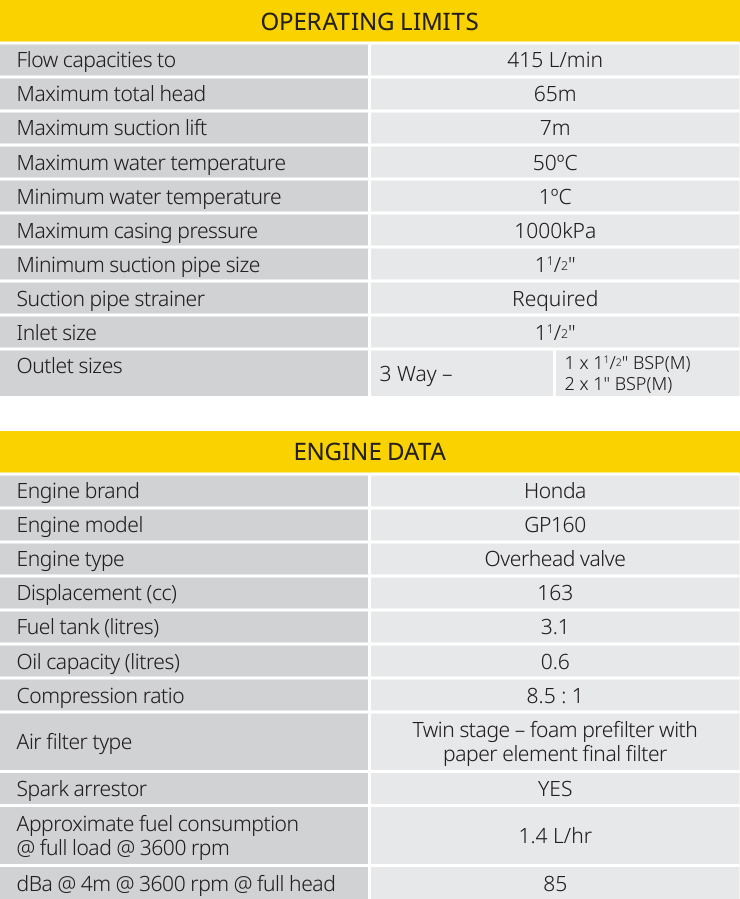

- Engine brand: Honda

- Engine model: GX160

- Engine type: Overhead valve

- Displacement (cc): 163

- Fuel tank (litres): 3.6

- Oil capacity (litres): 0.6

- Compression ratio: 8.5:1

- Spark arrestor: Yes

- Approx. fuel consumption @ full load @ 3600rpm: 1.73l/hr

- dBa @ 4m @ 3600rpm @ full head: 85

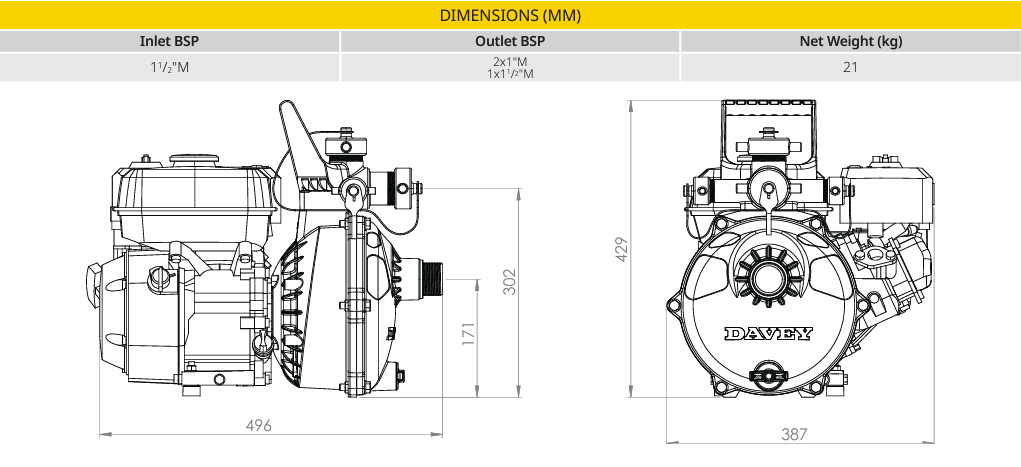

- Dimensions (LxWxH): 445mm x 388mm x 388mm

- Weight: 21kg

Freight Charges as below

Pick Up Dandenong South Free

Melbourne Metro $40

Victoria Regional $60

Sydney Metro $50

NSW Regional $80

Brisbane Metro $60

QLD Regional $90

Adelaide Metro $50

S.A. Regional $80

NT, WA, TAS metro $125

NT, WA, TAS regional $200

INSTALLATION AND PRIMING

• Fit strainer to bottom of suction pipe; a foot valve is not required.

• To prime, fill pump body with water then allow pump to run until drawing water.

WHY CHOOSE DAVEY Firefighter Single Stage Self Priming Pumps?

Patented clamped impeller design to enable longer impeller life, improved performance and easier disassembly in the case of blockage. Single stage design provides the versatility of high flow rates with strong pressure. Thrust balanced impeller design to extend engine life. Pump casing, diffusers and impellers manufactured from quality corrosion resistant marine grade aluminium for long life.

Choice of 3 or 4 way (dependant upon model chosen) discharge port for easy installation with a choice of plumbing sizes.

Polyester coated pump casing, exterior and interior, for added corrosion resistance. Patented floating impeller neckrings front and back. The front neckring helps improve pumping efficiency, the back neckring helps extend seal life and dramatically reduce engine wear.

Self priming from 7m for more versatile installation options. Large priming and drain port with bayonet fit plugs. Plugs have safety retention system, plus are available with 1/4” tapping to accept pressure gauges or drain cocks.Low-oil protection on all models – engines won’t start or run if oil level is inadequate, thus protecting your engine.

All engines conform to the tough environmental requirements of the USA EPA and CARB standards, to help look after the environment.

Are you Bushfire Ready?

Few people are ever fully prepared for an emergency like a bushfire outbreak and the speed at which the fire front can travel. Consequently they often allow little time to implement an effective fire defence. Davey and ASC Water Tanks has a list of recommendations for effective management and maintenance for consumers, ahead of the fire season.

1. Know the machine: All members of the household need to be proficient in the location, operation and fitting of attachments like inlet and outlet hoses to the fire pump. Equally as important, is to know where other protective materials like clothing and goggles are stored for quick retrieval.

2. Practice: A well rehearsed and documented fire plan is critical to personal survival. In the event a critical situation arises, investing a small amount of time now in pre-fire season training will be of vital importance if a fire situation occurs.

3. Fuel – Petrol: Many people fail to recognise that petrol has a limited life, losing its volatility and effectively becoming ‘stale’. Engines kept fuelled for long periods, often over winter, may not start due to the deterioration of its fuel. A simple and recommended solution is to change the fuel every two months, either by running the pump or draining it of fuel. Better still, both leading petrol engine manufacturers offer a fuel stabiliser which will dramatically extend the life of the fuel, but it must be added when new fuel is purchased.

4. Fuel – Diesel: Has a longer shelf life but it generally needs to be stored at low ambient temperatures to extend the storage time. Major fuel companies expect diesel fuel to have 12 months or longer life at an ambient temperature of 20ºC, or six months at an ambient temperature of 30ºC.

5. Engine oils are another consideration and individual engine manufacturers offer their own specially branded engine oils to best suit their engines. Synthetic multi-grade engine oil is NOT a

suitable alternative, so it is important to follow the manufacturer’s engine lubrication recommendations.

6. Running the engine regularly will ensure that oil is well distributed around the moving parts to provide best lubrication and a longer working life.

7. Air cleaners are another important consideration, to ensure your pump set has adequate clean air access. The air cleaner or filter needs to be checked and replaced as per the recommendation of the engine manufacturer.

8. Keeping the engine cool also has a dramatic effect on the power it can deliver. Protecting the pump from radiant heat in a flame proof enclosure is the ultimate solution, while adding a mist spray around the pump or its enclosure will aid cooling and humidify the air.

9. A general maintenance regime involving regular checks will ensure that fuel lines are in good condition, the recoil starter works and a regular service schedule is adhered to will pay dividends.

10. Check the plumbing: Time spent investigating and maintaining the water system is also important.

11. Check for leaves, debris and sticks: These can impede the inlet system, while for permanent installations, a foot valve and strainer at the end of the suction line can overcome obstructions.

12. The system should be checked for air leaks and to check that all gaskets and seals are in good order.

13. Having an underground ring main installed around your property with durable hydrant or standpipe outlets can give you much greater coverage and even shorter hoses with increased

resistance to ember attack.

So, as the summer fire season approaches the traditional motto of ‘be prepared’ applies. Establish your fire plan early. Adequately brief and train all family members in its resources and features. Finally, ensure that all your fire protection equipment from a Davey Firefighter pump, to your hoses and nozzles are well maintained and able to operate without delay