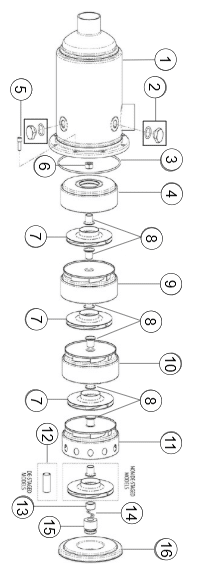

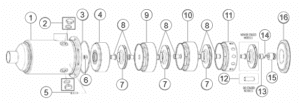

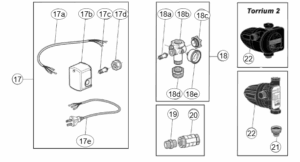

Davey HM Series Spare Parts Page

HM Series Multistage Pumps

Models: HM60-06, HM60-08, HM60-10, HM90-08, HM90-11, HM90-13, HM160-15, HM160-19, HM270-19, HM270-25

Notes:

- 2nd stage body comes with air valve assy which can be retrofitted onto models without the air valve. Subsequent stage bodies have the air hole which can also be retrofitted onto models that do not have the air valve already fitted.

- Washer cup part number 13666 – quantity of 1 required for HM60 & HM90 models (fitted to drive end side only) Quantity of 2 required for HM27- models (fitted to drive end & pump end).

- Washer cup part number 13693 – quantity of 2 required for HM160 & HM270 models (fitted to drive end & pump end).

- 2nd thermal O/load required on HM60-10T.

SERVICING INSTRUCTIONS

Tools required:

5mm Allen Key

Pozi Drive Screw Driver, 2 point

17mm Ring Spanner Socket

Flat Blade Screw Drive

Torque Settings:

Casing screw – 7-9Nm

Check valve – 4-7Nm

Impeller Nut – 10Nm

WARNINGS

- All electrical work to be performed by suitably qualified electrical personnel.

- Always disconnect from electrical supply BEFORE any work is carried out.

- Release pump pressure before undoing any pipe work.

- NOTE: For protection, the Davey pump motor is fitted with an automatic reset thermal overload, constant tripping of this overload indicates a problem. e.g. low voltage at pump, excessive temperature (above 50°C) in pump enclosure.

- WARNING: Automatic reset thermal overloads will allow the pump to restart without warning. Always disconnect the pump motor from the electrical supply before maintenance or repairs

- WARNING: When servicing or attending pump, always ensure power is switched off and lead unplugged. Electrical connections should be serviced only by qualified persons.

- Care should also be taken when servicing or disassembling pump to avoid possible injury from hot pressurised water. Unplug pump, relieve pressure by opening a tap on the discharge side of the pump and allow any hot water in the pump to cool before attempting to dismantle.

- IMPORTANT: DO NOT USE petroleum based fluids or solvents (e.g. Oils, Kerosene, Turpentine, Thinners, etc) on the plastic pump components or seal components.

HM SERIES MULTISTAGE PUMP DISASSEMBLY

- Disconnect the power supply and release the pump pressure before removing the pump to do any repairs.

- Remove the eight casing screws with a 5mm allen key turning anti-clockwise. Sit the pump on the fan cowl for easier removal of the screws.

- You may have to put a flat blade screwdriver between the casing and the back plate to pry it off.

- The first stage body should lift off and it should also have an oring with it. If it is not still attached to the stage body, check inside the casing to see if it is stuck to the inside. If so remove it and check for flat spots and tears.

- You will now see a stainless steel nut that holds the rest of the pump assembly in place. This is removed with a 17mm ring spanner. You will need to sit the pump horizontally and remove the fan cowl. Place a flat blade screwdriver into the slot in the rotor, hold it tight and give the spanner a sharp tap with a softhead mallet to loosen the impeller screw.

- Remove the impellers wear rings and stage bodies and check for wear or rub marks.

- Remove the mechanical seal and casing oring. Check for wear or signs of heat on the seal faces and rubber boot. Check the oring for tears or flat or pinched spot.

- The back plate can be removed by inserting a small punch through the holes in the motor end shield and tapping it off. Remove the slinger from the shaft. Check, clean or replace all parts before you reassemble the pump.

TROUBLE SHOOTING

- Pump not delivering water or not building up pressure.

May be caused by one or more of the following:-

- Pump not properly primed

- Foot valve leaking on suction lift

- Suction lift too high

- Suction piping not correctly sealed or holed allowing air to enter pump suction

- Blocked or worn impellers

- Insufficient water supply source

- Reverse rotation

-

- Motor not running.

May be caused by one or more of the following:-

- Power failure

- Blown fuse

- Motor overload tripped

- Motor windings faulty

-

- Motor thermal overload tripping

May be caused by one or more of the following:-

- Low voltage supply

- Motor or pump seized

- Motor windings faulty

- Frequent cycling

-

- To check for correct automatic pressure system operation:

-

- Close gate valve at pump outlet, allowing pump to run and build up pressure until it switches off at cut-out setting of pressure switch or Hydrascan®.

- Open gate valve at pump outlet to allow water to discharge to an outlet point. Pump will automatically switch on at cut-in setting of pressure switch or Hydrascan.

-

- Pump switching on and off frequently when no taps are turned on

May be caused by one or more of the following:-

- Leaking footvalve or in-line checkvalve

- Water leaking from suction or delivery piping

- Ball valve in toilet cistern, hot water system, or stock troughs allowing unit to overflow

- Pressure tank not retaining air pressure or air change too high (pressure switch model only)

-

- Pump not switching off or taking too long to switch off (Pressure Switch model only)

May be caused by one or more of the following :-

- Voltage supply too low

- Leak in discharge pipe or fitting, taps etc.

- Worn or blocked pump components, impeller, casing etc.

- Drop in water level in water supply source

-