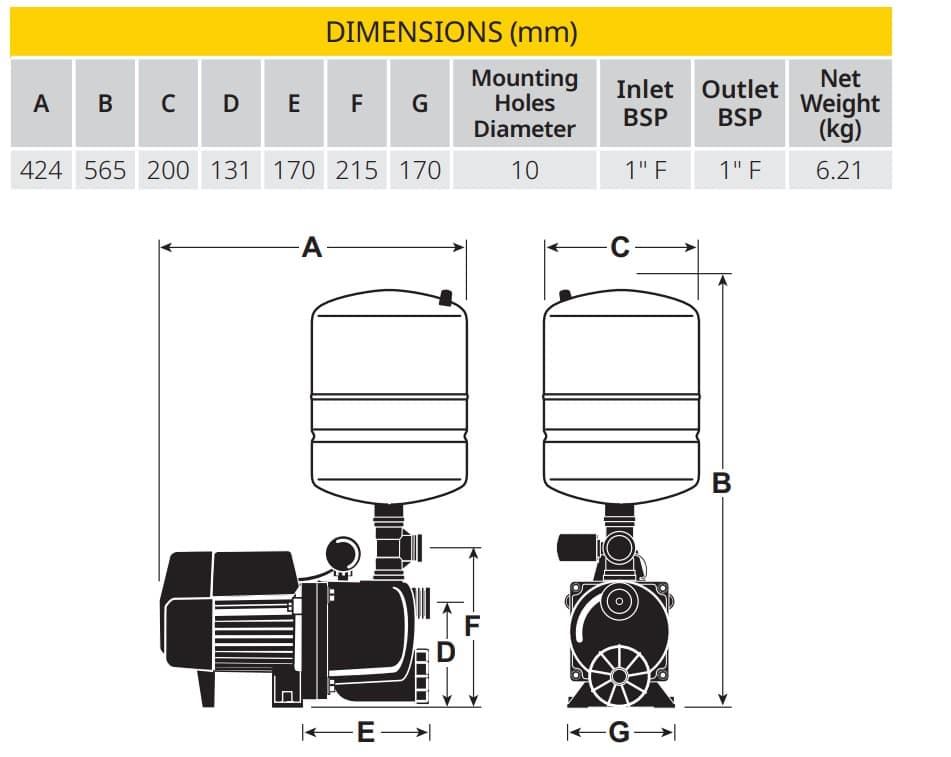

Davey XP25P8 Pressure Controlled System with 8LT Pressure Tank

XP Water Pressures Systems are a robust and compact single stage jet assisted water pump, suitable for small to medium sized single storey households with varying water quality.

The XP water pressure systems have been certified and tested to comply with the requirements of the AS/NZS 4020 standard. The AS/NZS 4020 standard stipulates that products in contact with drinking water do not affect the taste or appearance of the water, do not support the growth of micro-organisms and do not release cytotoxic or mutagenic compounds or metals into the water.

The unit features a TEFC corrosion resistant motor driven by a single stage, jet assisted centrifugal pump and includes a built in pressure accumulator with a “Supercell” 8P tank which provides 3 litre draw-off.

APPLICATIONS:

Ideal for pressure boosting applications for:

- Suburban homes – pressurising drinking water from rain water tanks.

- Small weekenders / cottages – delivering pressurised water from rainwater catchment tanks

- Caravans

- Boats (240V A.C. power)

BENEFITS:

• Manufactured from quality corrosion resistant materials

• Motor and pump designed for frequent starts

• Discharge may be rotated through 180º – makes plumbing easier

• Quick and easy installation

• Low maintenance

• Easy to service if required

• Every pump is performance and pressure tested in our factory to ensure quality and reliability

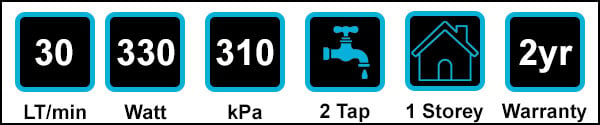

Motor / power: 330W

Max. flow: 30T/min

Head: 31m

Inlet: 1″F / 25mm

Outlet: 1″F / 25mm

Pressure: 310kPa

Body: Glass filled nylon

Impeller: Glass filled polycarbonate

Mechanical Seal : Carbon Synthetic

Warranty on pump: 2 Years

Economical, compact 25lpm jet assisted centrifugal pressure pump. The unit features a TEFC motor and includes a built in pressure accumulator. Why choose the Davey XP Pressure Pump?

Single stage jet assisted centrifugal pump

- Higher operating pressures

- Less moving parts for increased dependability

Corrosion resistant engineered thermoplastic pump components

- Longer life when pumping a variety of water qualities

- Reduced friction within the casing and impellers

- Pump feet provide outstanding life even when installed on wet surfaces

In-built compact accumulator and pump casing for

- Easier installation in small spaces

- Longer accumulator life

Internal suction check valve for easier installations High quality purpose built 2 pole IP55 Davey pump motors with

- Choice of 220/240 volt, 50/60Hz, 2850rpm or 110/115 volt, 60Hz, 3420 rpm to suit almost every supply voltage

- Permanent split capacitor starting for dependable and frequent starting everytime

- In-built thermal overload for long motor life and protection against motor damage due to jamming

- High quality C3 – HTG rated fully sealed bearings for longer life

- Fitted with a 2m long power lead with 10amp Australian three pin plug for ease of connection to power supply

Designed with the serviceman and installer in mind

- Suction and discharge are close for easier installation

- Quality components throughout for long life and easier maintenance

Every pump is performance and pressure tested in our factory to ensure quality and reliability

ELECTRICAL DATA

Model XP25P8

Supply Voltage 220-240V

Supply frequency 50Hz

Nominal speed 2850rpm

Input power (P1) 0.54kW

Output power (P2) 0.33kW

Full load current 2.3 amps

Locked rotor current 12 amps

Starting P.S.C.

Enclosure class IP55

Insulation class Class F

Pressure switch cut-in 140kPa

Pressure switch cut-out 280kPa

MATERIALS OF CONSTRUCTION

Impellers Glass filled polycarbonate

Pump casing Glass filled nylon

Pump shaft 304 stainless steel

Internal check valve Delrin

Check valve spring 304 stainless steel

Seal ring (stationary) Ceramic

Seal ring (rotating) Carbon

Seal ring elastomer Nitrile rubber

Seal spring 304 stainless steel

O-rings Nitrile rubber

Jet Acetyl

Venturi/coverplate Glass filled noryl

Priming plug Glass filled polypropylene

Motor shell Marine grade aluminium

Motor shell finish Baked polyester

Pressure tank shell Steel

Pressure tank shell finish Epoxy primer with polyurethane epoxy finish

Pressure tank diaphragm Butyl rubber

Pressure tank liner Potable grade virgin polypropylene

Pressure tank inlet Stainless Steel

INSTALLATION AND PRIMING

• On installations with suction lifts over 1m, a good quality foot valve should be fitted to avoid loss of prime. In this case the check valve inside the pump should be removed.

• The system is primed by removing the pressure tank, filling with water and replacing the tank prior to switch on.

• For suction lifts over 1.5m the pressure switch may need to be adjusted to enable the pump to automatically cut-out.

• Fill pump and suction lines through pressure switch port.