Grundfos MAGNA1 25-120 N Stainless Steel Circulator Pump – 99221227

Looking for a circulator pump that will get the job done? Look no further. Combining cost-efficiency with simplicity and reliability, MAGNA1 25-120 N offers the ideal solution. In short, MAGNA1 25-120 N is a simple, energy-efficient circulator pump. Built on tried and tested MAGNA1 25-120 N technology, it offers a cost-efficient solution for jobs in which simple control and monitoring features are sufficient. Compared to the previous edition, MAGNA1 25-120 N offers improved technology as well as unmatched levels of energy-efficiency, reliability and user-friendliness strengthening its position as one of the best circulators for simple solutions.

Suitable For:

- Heating surfaces.

- Air-conditioning surfaces.

- Ground-source heat pump systems.

- Smaller chiller applications.

| Max Power Unit | 188W |

| Mains Frequency | 50 / 60 Hz |

| Rated Voltage | 1 x 230 V |

| Pumped Liquid | Water |

| Liquid Temperature Range | -10 to 110°C |

| Rated Flow | 9.5 litres / min |

| Rated Head | 12 meters |

| Pump Housing | Cast Iron |

| Impeller | Stainless Steel |

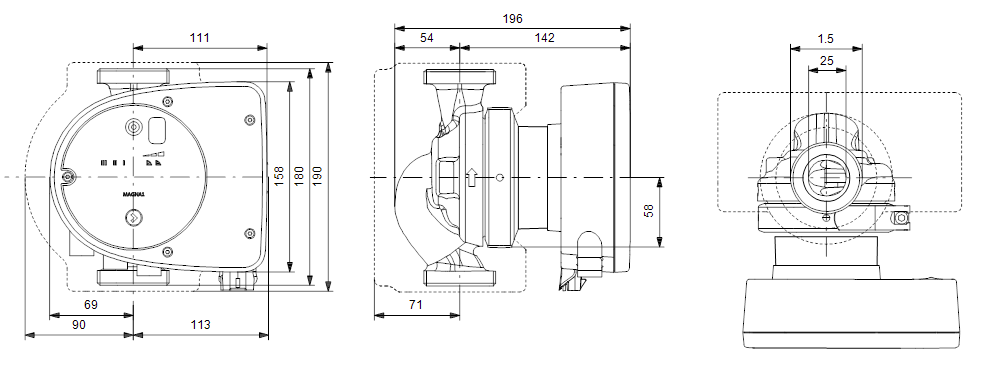

| Port to Port length | 180mm |

| Type of Connection | G |

| Size of Connection | 1 1/2 inch |

A CLOSER LOOK AT THE INPUT/OUTPUT

Potential-free relay, normally closed:

In a potential-free relay with a normally closed function, the relay opens whenever a fault occurs, ensuring that you’ll be notified if a wire breaks, for instance. Grundfos utilises proven, reliable technology for its relay functionalities, providing a very robust solution on both low and high voltages.

Digital start/stop operation:

The pump can be set to start or stop by means of external input. For instance, if it’s set in weather compensation control, the pump will stop if the outside temperature changes.

Installer-friendly terminal plugs:

Standard installer-friendly plugs provide easy accessibility and make it easier for the installer to find a spare part if, for instance, a plug is lost during installation. In addition, you can test the relay function by removing the terminal plug. In such a scenario, it will be perceived as a fault in the pump, which may be helpful in connection with BMS programming and troubleshooting.

COMMISSIONING BY THE PUSH OF A BUTTON

MAGNA1 was built with simplicity in mind – something that’s evident in the pump’s user interface, where the pump can be commissioned by means of just one button. This is also a direct advantage when replacing older 3-speed circulators of the same size.

NINE CONTROL FUNCTIONS:

MAGNA1 has nine predefined control functions, which makes it easy to select the optimum one for the application at hand. There are three proportional pressure curves, three constant pressure curves and three constant speeds. The pump is factory set to run in proportional pressure curve 2. The control function can be changed by means of the button on the interface.

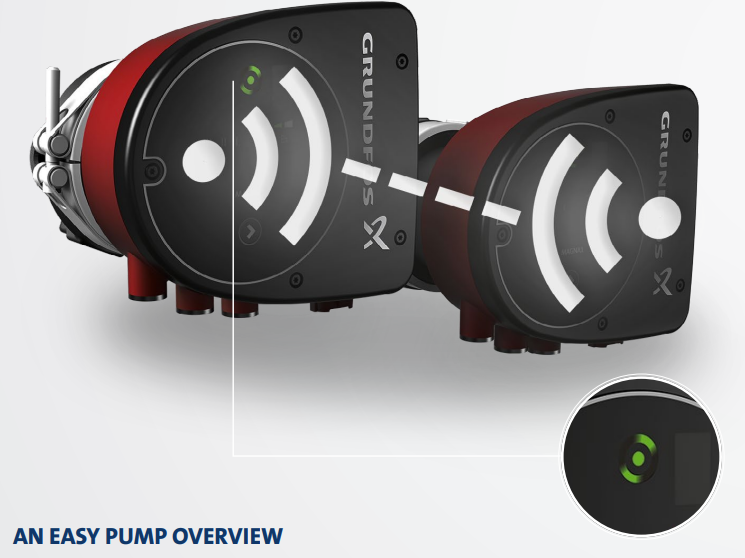

THE GRUNDFOS EYE:

The Grundfos Eye is your way of understanding your pump’s status. It gives you a perfect and fast pump performance status, which comes in handy when performing normal operation inspection and troubleshooting scenarios in a boiler room.

SIMPLE USER INTERFACE:

The light fields in the LED display provide a clear overview of which of the nine control functions the pump is operating in.

GOING WIRELESS:

TWIN PUMP FUNCTIONALITY

One of the features of MAGNA1 is its twin pump functionality, in which both pumps alternate to

share the pump load over time. That way, one is redundant, and can take over if the other is not able to perform. Both pumps can handle the full flow individually – ensuring a security of supply. The two pump heads communicate wirelessly and can reach flow levels of up to 70m3/h.

The alternating function is specifically implemented in twin products, in which two heads share

the same pump housing, thereby optimising installation costs. The function is factory-enabled, but it can easily be switched off by pressing the button on the user interface of one of the pumps for 5 seconds. In order to prevent wear on the output relay of the external controller, it is recommended that you use the digital input to remotely control the pump heads.

The twin pumps are connected from the factory. The centre of the Grundfos Eye will light up green if the connection is successful. If the two heads lose connection, it will issue a warning on the user interface. Additionally, you can use Grundfos GO to configure whether this warning should be visible on the relay.