Grundfos MAGNA3 32-120 F N Stainless Steel Circulator Pump – 97924346

The MAGNA3 32-120 F N is a circulator pump based on the tried and tested MAGNA3 32-120 F N technology and our industry-leading experience with electronic pumps. The permanent magnet motor, AUTOadapt function and integrated frequency converter is still part of the MAGNA3 32-120 F N package, but we’ve added some additional, ground-breaking new technologies. The result is a cutting-edge piece of intelligent technology that retains the unrivalled Grundfos reliability.

MAGNA3 32-120 F N is a single-phase pump and characterised by having the controller and control display integrated in the control box. The pump also has a built-in differential-pressure and temperature sensor. The pump housing is available in both cast-iron and stainless-steel versions. The composite rotor can is carbon-fibre reinforced, the bearing plate and rotor cladding are made of stainless steel and the stator housing is made of aluminium. The power electronics are air-cooled. MAGNA3 32-120 F N incorporates a 4-pole synchronous, permanent-magnet motor (PM motor). This motor type is characterised by higher efficiency than a conventional asynchronous squirrel-cage motor. The pump speed is controlled by an integrated frequency converter.

Suitable For:

- Mixing loops

- Heating surfaces

- Air conditioning surfaces

- Ground-source heat pump system.

- Smaller chiller applications.

| Max Power Unit | 333W |

| Mains Frequency | 50 / 60 Hz |

| Rated Voltage | 1 x 230 V |

| Pumped Liquid | Water |

| Liquid Temperature Range | -10 to 110°C |

| Rated Flow | 11.22 litres / min |

| Rated Head | 7.239 meters |

| Pump Housing | Cast Iron |

| Impeller | Stainless Steel |

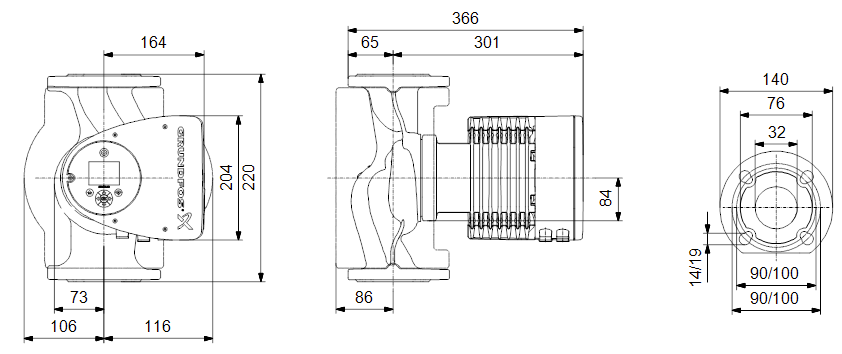

| Port to Port length | 180mm |

| Type of Connection | G |

| Size of Connection | 1 1/2 inch |

The highest standards, the greatest results

Ready for range?

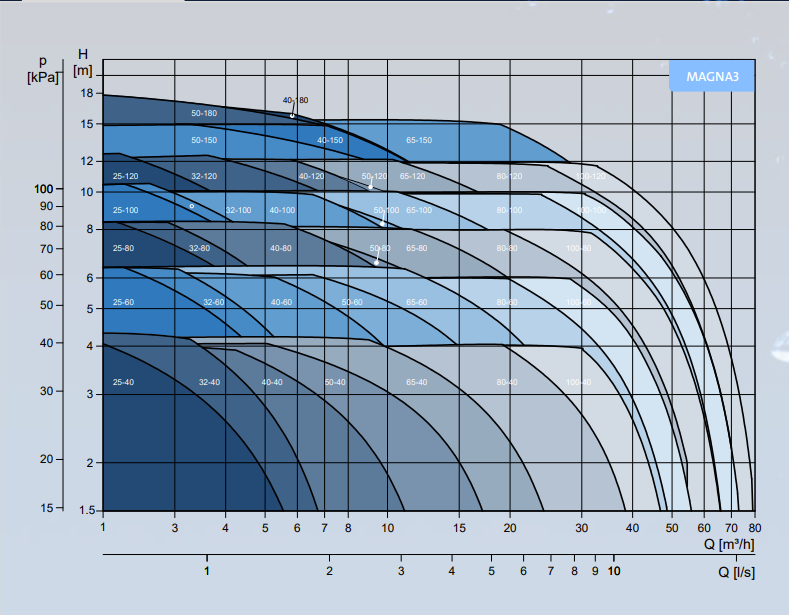

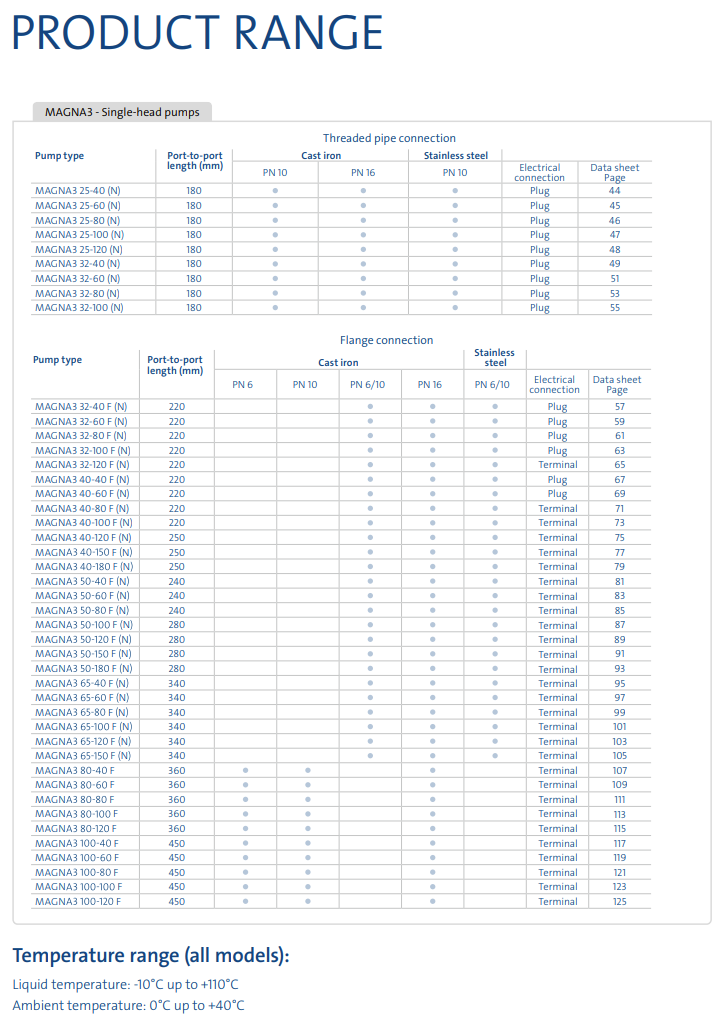

MAGNA3 is a truly full-range pump with more than 200 different single and twin circulators in cast iron or stainless steel. We have also increased the maximum twin to 18 m and the flow to 70 m3/h. Get ready to specify a perfectly sized circulator pump for any HVAC application.

The smart pump

MAGNA3 gives you new opportunities with more intelligent control modes, optimized building

management communication and a built-in heat energy meter. It also allows you to save pump

throttling valves in the system. It is fair to say that we have raised the bar for intelligent pumping

Efficiently the best

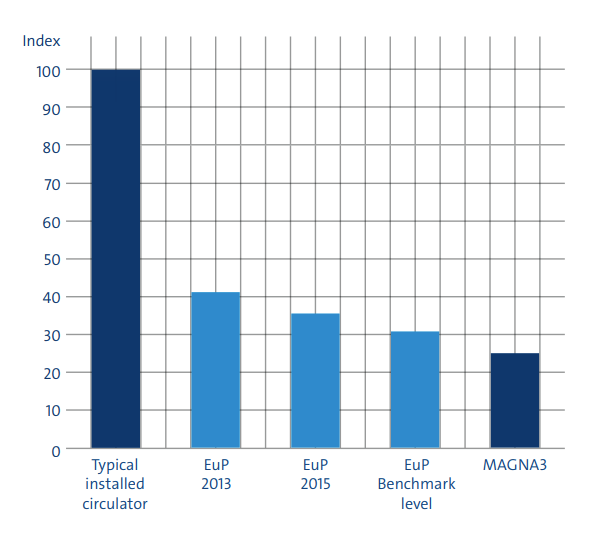

The short version is this: MAGNA3 is the most efficient circulator available on the market today.

The longer version is this: With an Energy Efficiency Index (EEI) well below the EuP benchmark level you can achieve energy savings of up to 75% compared to a typical installed circulator and thereby a remarkably fast return on investment. And of course it more than meets the standards for EuP legislation (learn more at www.europump.org).

Reliable from A to Z

At Grundfos we do not take testing lightly. With 40 years of experience with electronically controlled pumps and 1 million test hours for the MAGNA3 in extreme conditions, including alternating pressure tests, high humidity tests as well as high and lowtemperature tests, we are confident that this pump will serve you day in and day out for many years to come.

Full range means perfect fit

The extended MAGNA3 range with maximum heads of 18 m and maximum flows of 70 m3/h features more than 200 single and twin pumps in cast iron or stainless steel. This means that it is much easier to right-size the MAGNA3 for any duty point and cut both purchase and energy costs in the process.

MAGNA is always improving

Grundfos continues to set the pace for circulator pumps and is the obvious choice if you are looking for the most energy-efficient solution and fastest return on investment. To achieve the groundbreaking MAGNA3 energy efficiency, we have further optimized pump hydraulics

and incorporated our patented differential pressure sensor, while switching to a composite rotor can and a compact stator that minimizes losses in the motor. The result is a highly efficient and future-proof circulator with an EEI value that makes even the strict 2015 EuP requirements look old-fashioned.

The all-purpose circulator

Like its predecessor, MAGNA3 is the ideal pump for heating and cooling applications as well as domestic hot water circulation systems. It is designed to handle liquids down to -10°C, which makes it suitable for both tough industrial tasks and ground source heat pump systems (GSHP). Furthermore, the liquid temperature (-10°C to +110°C) is now independent of the ambient temperature (0°C to +40°C). So whether your project requires heating or cooling – MAGNA3 is

the pump for you.

Refurbish and save money

Did you know that a pump system refurbishment can result in energy savings of up to 80%? Grundfos offers several approaches to energy refurbishment, depending on the condition of your current pump system. For more information, please contact your local Grundfos representative.

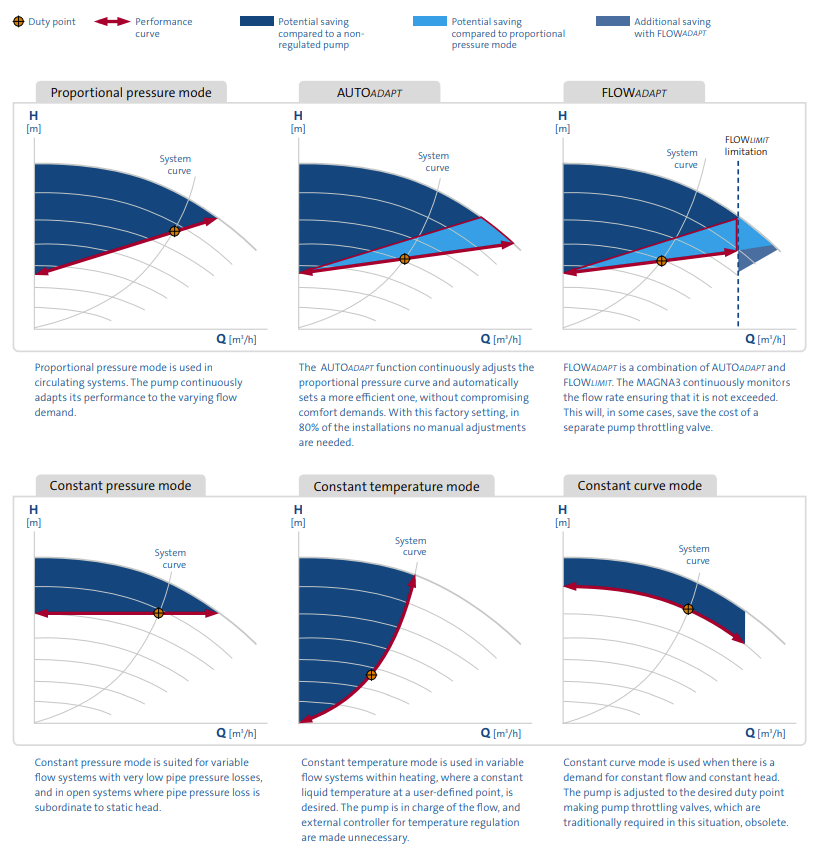

Intelligent control saves time and energy

The MAGNA3 gives you the full range of control mode options you would expect from a state-of-the-art circulator pump. But the intelligent modes – AUTOADAPT and FLOWADAPT – set MAGNA3 apart from the competition. Furthermore, the FLOWLIMIT and Automatic Night Setback control functions are applicable with all MAGNA3 control modes.

INTELLIGENT SOLUTIONS

Built for building management

Optional CIM modules support all common fieldbus standards, making MAGNA3 the perfect addition to any BMS system.

Heat energy meter

The MAGNA3 features a built-in heat energy meter that can monitor system heat energy distribution and consumption in order to avoid excessive energy bills caused by system imbalances. The heat energy meter has an accuracy of +/-10%, depending on the duty point, and will save you the cost of installing a separate energy metering device within your system.

No pump throttling valves

The new FLOWLIMIT function and FLOWADAPT control mode allow you to set a maximum flow limit for your MAGNA3 pump. The pump continuously monitors the flow rate to ensure the desired maximum flow is not exceeded. This eliminates the need for pump throttling valves and hereby improves the system’s overall energy-efficiency. To meet system flow limitations, the pump will adjust its performance to a given setpoint, which dramatically cuts energy consumption.

Wireless communication between two single pumps

MAGNA3 is supplied with wireless technology which enables it to connect to another MAGNA3 pump. Using the built-in wizard, connection to a parallel coupled pump is quick and easily obtained. The two pumps are now controlled jointly in either cascade mode, alternating mode or pump back-up mode.

More I/O for system intelligence

With the addition of an extra configurable relay and an analog input, the complete MAGNA3 I/O package allows for better system monitoring and optimal pump regulation.

MAGNA3 I/O package

1 x analog input (0-10V/4-20mA) for differential pressure sensor, constant temperature control, heat energy metering or external set point

2 x relay outputs configurable as alarm, ready or operation

3 x digital inputs for external start/stop, max. curve and min. curve

Easy optimisation

The innovative 3D Work Log and Duty Point Over Time curve make optimisation simple and accurate. The two new features give you the details of the pump’s performance since the day it was installed as well as the details of its operating conditions, such as average temperature and power consumption. Based on this, it is easy to find the optimal replacement pump, perfect optimisation plan or carry out troubleshooting.