Grundfos SEG.50.40.E.EX.2.50B Submersible Grinder Pump

Part No. 99274439

2 Year Standard Warranty

The SEG AUTOadapt range of grinder pumps from Grundfos is specifically designed for pumping effluent and untreated domestic sewage in small communities or sparsely populated areas with no sewer systems or where gravitation systems are unsuitable.

Pressurised systems are the perfect choice for transfer of effluent and domestic sewage, and the SEG AUTOadapt range combines cost-effectiveness with maximum protection for the environment by facilitating the use of smaller pressure pipes for minimal investment costs.

The SEG AUTOadapt range is designed to reduce energy consumption and to keep downtime costs to a minimum, while maintaining peak performance throughout the lifetime of the system. The foam-drain function utilises random start and stop levels to ensure that the floating layer doesn’t accumulate and solidify.

Designed for dependability, efficiency and cost-effectiveness The SEG AUTOadapt range of pumps is designed for the transfer of domestic and municipal wastewater in:

• Sparsely populated areas

• Small villages and farms

• Areas of difficult topography

• Areas with high groundwater

In addition, the SEG AUTOadapt range of pumps can remove industrial wastewater containing fibres in industrial applications.

The Grundfos patented grinder system ensures the reliable and efficient grinding of solids to even smaller pieces. In addition to extremely effective and reliable operation, service is easy, with quick dismantling for replacement of wear parts requiring no special tools.

Benefits

1. Output for alarm relay.

The pump has relay output for alarm. Output of NC and NO can be used for visual or acoustic signaling devices.

2. In case of power cut, random start delay is enabled.

3. The pump has a safety feature that verifies correct phase sequence before starting.

4. The pump resets its parameters and calibrates itself after a complete cycle.

5. The pump has an anti-seize protection feature.

The anti-seizing feature ensures the pump is permitted to run and is started at set intervals to ensure the impeller does not seize. For the Ex versions, this is valid only as long as the dry run sensors are submerged.

Design and Materials

The pump’s main structure is made of cast iron, and its surface is smooth to prevent dirt and other impurities from accumulating. A stainless steel clamp connects the motor to the pump, which prevents corrosion and simplifies servicing. The power cable includes strands for thermal sensors to monitor the motor’s winding temperature. It also uses a sealed plug connection to prevent moisture ingress, even if the cable is broken or handled roughly.

Safety and Certification

The pump must be connected to a controller along with an intrinsically safe barrier, such as the Grundfos LC-Ex4, to ensure safe operation. The pump has received approval from VTT under the ATEX Directive, which is why the approval logo is visible on the pump.

Suitable for

- Water treatment – Commercial buildings

- Domestic wastewater

- Wastewater transport

- Flood control

Technical Specifications

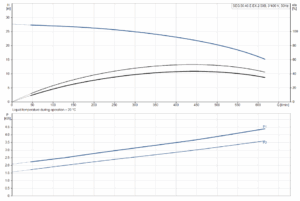

Max Flow: 617L/min

Max Head: 26.8m

| Controls: | ||

| Moisture sensor: | without moisture sensors | |

| AUTOADAPT: | Yes | |

| Liquid: | ||

| Liquid temperature range: | 0 – 40 °C | |

| Selected liquid temperature: | 20 °C | |

| Density: | 998.2 kg/m³ | |

| Technical: | ||

| Type of impeller: | GRINDER SYSTEM | |

| Primary shaft seal: | SIC/SIC | |

| Approvals: | PA-I, ATEX | |

| Curve tolerance: | ISO9906:2012 3B2 | |

| Materials: | ||

| Pump housing: | Cast iron | |

| EN1561 EN-GJL-200 | ||

| Impeller: | Cast iron | |

| EN1561 EN-GJL-200 | ||

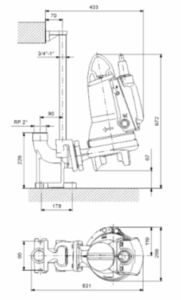

| Installation: | ||

| Maximum ambient temperature: | 40 °C | |

| Maximum operating pressure: | 600 kPa | |

| Flange standard: | DIN | |

| Pipework connection: | DN 50 | |

| Pump outlet: | DN 50 | |

| Pressure rating: | PN 10 | |

| Maximum installation depth: | 7 m | |

| Auto-coupling: | 97695874 | |

| Electrical data: | ||

| Power input – P1: | 5.2 kW | |

| Rated power – P2: | 4 kW | |

| Mains frequency: | 50 Hz | |

| Rated voltage: | 3 x 400-415 V | |

| Voltage tolerance: | +6/-10 % | |

| Max starts per hour: | 30 | |

| Rated current: | 8.2/8.2 A | |

| Starting current: | 43 A | |

| Rated current at no load: | 3.5 A | |

| Cos phi – power factor: | 0.92 | |

| Cos phi – p.f. at 3/4 load: | 0.89 | |

| Cos phi – p.f. at 1/2 load: | 0.81 | |

| Rated speed: | 2830 rpm | |

| Moment of inertia: | 0.011 kg m² | |

| Motor efficiency at full load: | 82 % | |

| Motor efficiency at 3/4 load: | 82 % | |

| Motor efficiency at 1/2 load: | 80 % | |

| Number of poles: | 2 | |

| Start. method: | direct-on-line | |

| Enclosure class (IEC 34-5): | IP68 | |

| Insulation class (IEC 85): | F | |

| Explosion proof: | yes | |

| Ex-description: | II 2 G EX DB IIB T4/T3 GB | |

| Explosion protection standard: | EN 60079 | |

| Length of cable: | 10 m | |

| Cable type: | LYNIFLEX | |

| Type of cable plug: | No plug | |

| Others: | ||

| Net weight: | 82.9 kg | |

| Danish VVS No.: | 3913444492 | |

| Country of origin: | HU | |

| Custom tariff no.: | 8413709019182742 | |

How to Dismantle & Assemble Grundfos SEG AutoAdapt