ZEN-APG750/2/G50HA0FTEX – Zenit Grey High Head Pump – 807403

APG Suitable for

Suitable for clear wastewater, rainwater and seepage. The considerable head guarantees excellent results for the creation of water features and decorative fountains; suitable for use in agriculture, irrigation and the fish processing sector.

Suitable for use in underground carparks.

ATEX certified Ex d.

Technical Specifications

| Brand | Zenit Pumps |

| Product Type | Submersible Pump |

| Suitable For | Water |

| Approval | ATEX certified Ex d. |

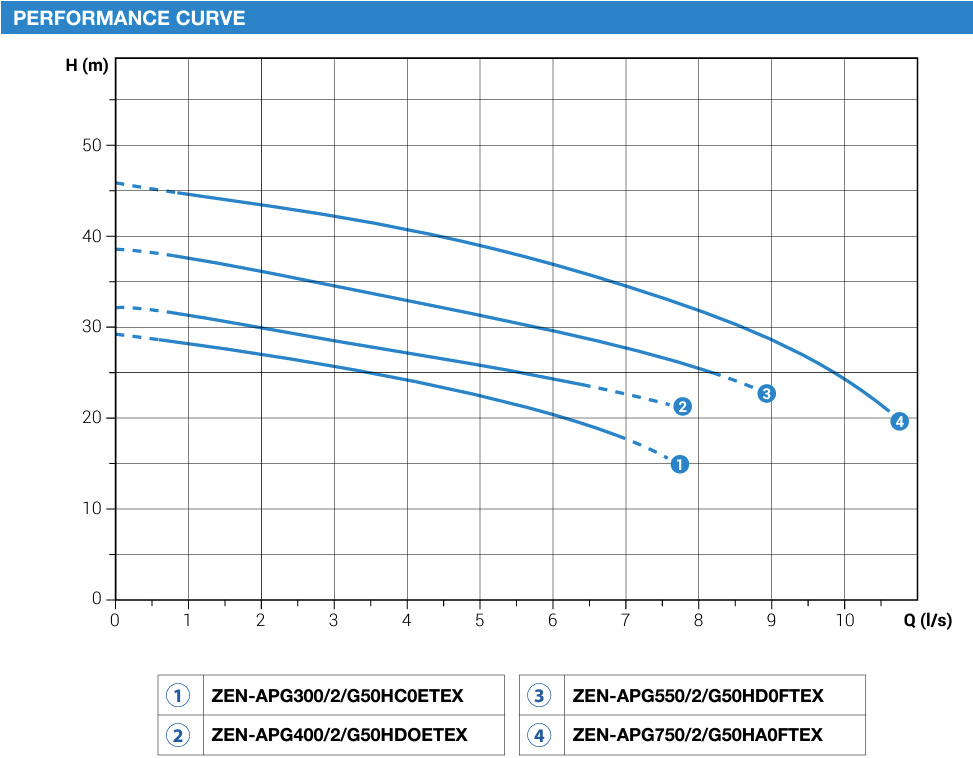

| Max Flow (L/sec) | 10.3 |

| Kilo Watts | 5.5 Kw |

| Max Head (m) | 44.7 |

| Port Size Outlet | G 2″ – DN32 |

| Series | Grey |

| Warranty (months) | 12 |

| Volts | 415 V |

Zenit Grey pumps feature cleverly redesigned hydraulics and motors to guarantee high performance, low consumption and outstanding versatility. These all translate to greater product efficiency, impeccable reliability and lower operating costs.

Efficient & Reliable

The Zenit Grey series offers reduced purchasing, installation and maintenance times and costs thanks to a wide choice of models and the use of immediately available standard components.

Exceptionally reliable, the Grey series needs far fewer repairs, meaning reduced costs. Running costs will be lower and there will be fewer system stoppages, allowing more effective maintenance scheduling.

| Construction materials | |

|---|---|

| Motor casing | Cast iron GJL-250 |

| Impeller | Cast iron GJL-250 |

| Mechanical seals | Two in silicon carbide (2SiC) |

| Nuts and bolts | Stainless steel – class A2-70 |

| Standard gaskets | NBR |

| Drive shaft | AISI 431 Stainless Steel |

| Painting | Bicomponent epoxy paint with high resistance to corrosion |

| Operating specifications | |

|---|---|

| Max operating temperature | 40°C |

| pH of liquid | 6 ÷ 14 |

| Liquid viscosity | 1 mm2/s |

| Max submergence | 20 m |

| Liquid density | 1 kg/dm3 |

| Max acoustic | <70 dB |

| Max. starts/hour | 20 (<10 kW) 15 (>10 kW) |

Features

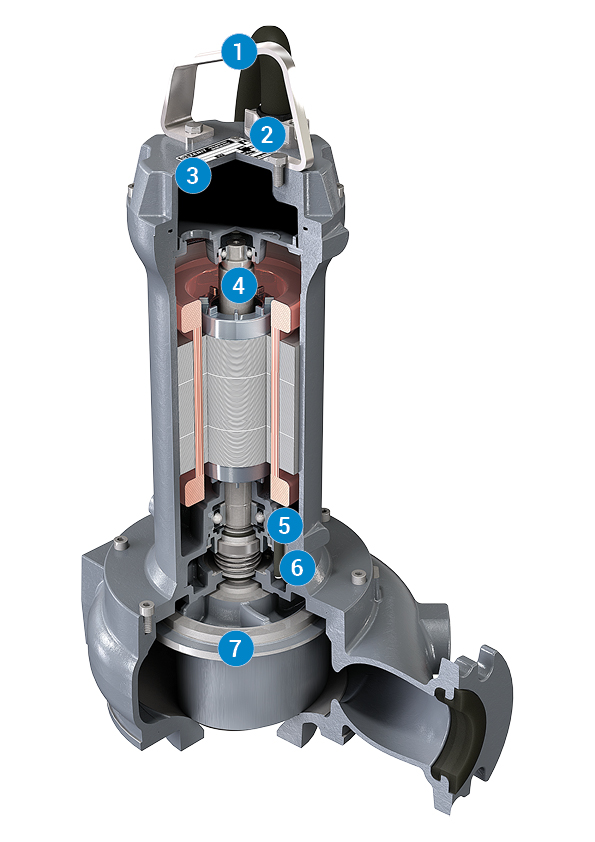

Rugged stainless steel lifting and carrying handle.

The universal GAS thread of the cable gland is able to take a sheathing pipe to protect the power cable from mechanical or chemical damage due to urbulence or the aggressive nature of the liquid.

Every model undergoes pressurised testing to guarantee perfect assembly and operation of the gaskets, cable gland and mechanical seals.

Drive shaft in AISI 431 stainless steel. Connection to impeller via tapered coupling.

Two mechanical seals in silicon carbide (SiC-SiC) enclosed in an inspectable oil chamber. This prevents all contact between the mechanical seals and any solids or filaments in the wastewater.

Large, inspectable oil chamber to guarantee longer mechanical seal lifetime. Includes a leakage detection sensor.

The special conformation of the hydraulic part ensures the expulsion of solids and prevents fouling of the impeller.