Zenit DRBLUE100/2/G32VMGEX Floated Drainage Pump 800343

The new series of submersible drainage pumps for domestic use. DR (DRENO) version with multi-vane fully submerged technopolymer impeller for efficient operation, float switch optional on single-phase versions.

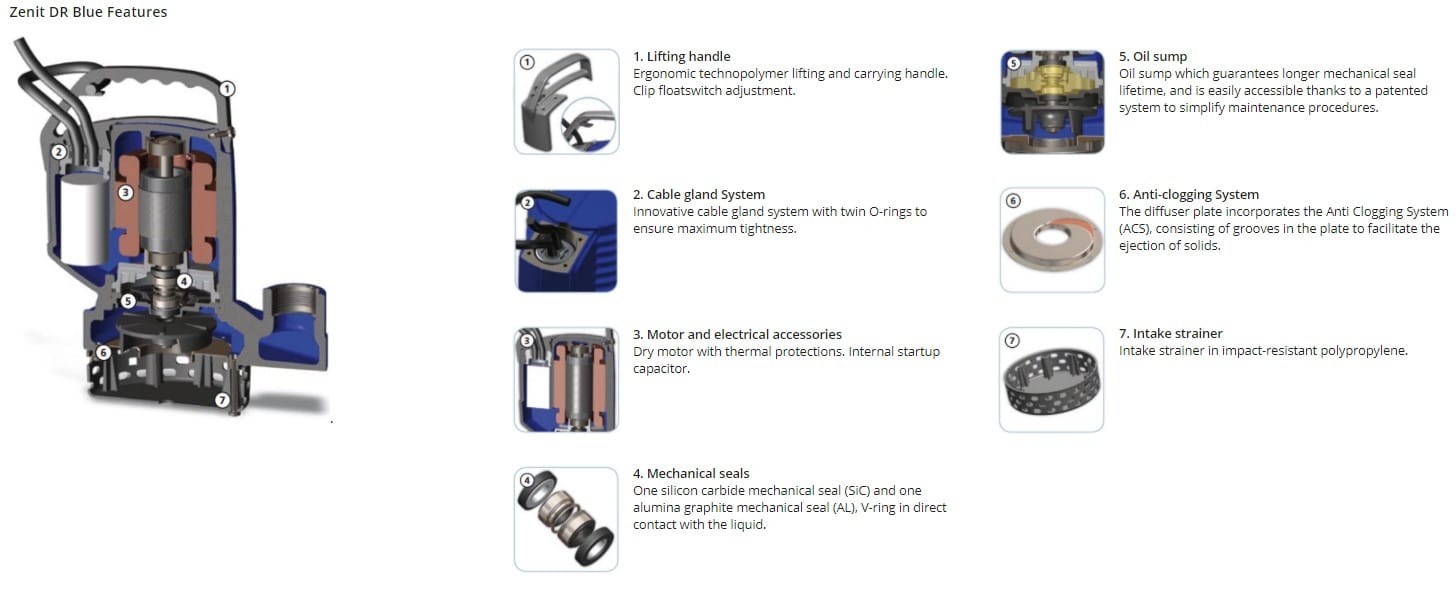

Comes complete with 10m power lead (with 3 pin plug on single-phase pumps)to suit outdoor installations. Patented sealing system incorporating dual silicon carbide / graphite alumina mechanical seals in oil bath for a longer seal life. Anti-stressing system for power cable reduces cable damage and water entry. Cable holder grommet built into handle allows adjustment of float switch cable length. Includes a cast iron pump body for durability, a suction screen to keep out hard solids and an ergonomic plastic carry handle for safety and comfort.

Suitable for:

• Clean or slightly soiled water containing small solids

• Stormwater dewatering from under houses, yards and ponds

• Groundwater seepage, rainwater collection

• Water features

• Car parks, truck stops, vehicle workshops, bus depots and garages

Technical Specifications

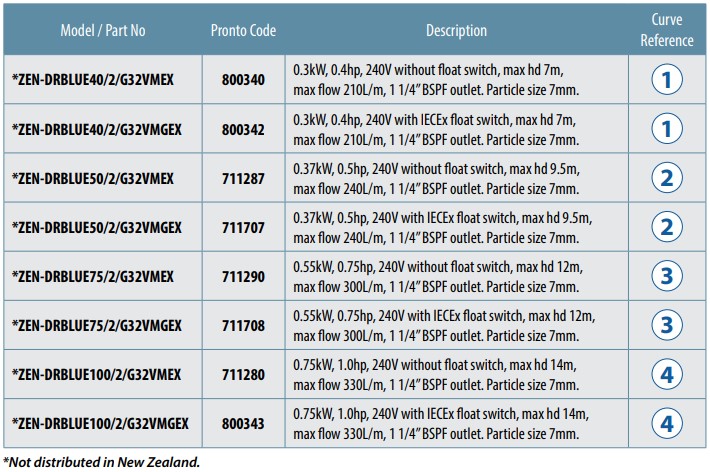

| Brand | Zenit Pumps |

| Product Type | Submersible Pump |

| Bar | 1.4 Bar |

| Approval | IECex Zone 2 Approved |

| Flow Range Category | d. 300 – 399 L/min |

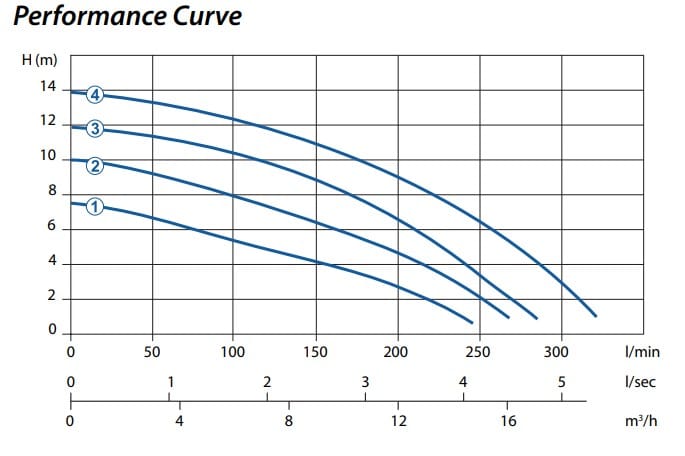

| Flow Rate (L/min) | 330 L/min |

| Hp | 1 Hp |

| Kilo Watts | 0.75 kW |

| Head Range Category | a. 0 – 39 m |

| Max Head (m) | 14 m |

| Port Size Outlet | 1 1/4″ BSPF outlet |

| Particle Size | 7 mm |

| Volts | 240 V |

| Watts | 750 W |

IECEx Zone 2 Approved

IECEx is the IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres. It uses quality assessment specifications that are based on International Standards prepared by the International Electrotechnical Commission (IEC).

Zenit Submersible Pumps exceed the new standard.

As one of the leading names in water treatment technologies, this pump have been awarded the IECEx – the international certification covering the use of equipment and services in explosive conditions.

So what is a ‘hazardous area’?

You can’t be too careful in hazardous areas – which is any space where flammable liquids, vapours, gases or combustible dusts could occur in high enough quantities to cause a fire or even an explosion.

These include:

- car parks

- truck stops

- vehicle workshops

- bus depots

- and garages

Constructive characteristics:

- Outlet: G1″¼

- Outlet orientation: V (vertical)

- Type of starting: D

- Weight: 15.5 kg

- Standard cable type: H07RN-F 3G1

- EX cable type: N.A.

- Standard paint type: Bicomponent epoxy paint

- Maximum acoustic pressure: 70 dB

- Set of standard mechanical seals: One Silicon carbide mechanical seal (SiC) and One CarbonAluminium oxide mechanical seal (AL)

Use limits:

- Maximum operating temperature: 40 °C

- Maximum immersion depth: 20 m

- PH of treated fluid: 6 to 14 pH

- Max starts per hour: 30

Test limits:

- Density of treated fluid: 1 Kg/dm³

- Viscosity of treated fluid: 1 mm²/s

Materials:

- Case: Grey Cast Iron – EN-GJL 250 (02)

- Shaft: Stainless Steel – AISI 420 (23)

- Cooling jacket: Not applicable (00)

- Standard gasket: Rubber – NBR (77)

- EX gasket: Not applicable (00)

- Nuts and bolts: Stainless Steel – Class A2-70 (42)

- Hydraulic: Grey Cast Iron – EN-GJL 250 (02)

- Impeller: Plastic (73)

- Cutting disk: Not applicable (00)

- Cutter: Not applicable (00)

- Grid: Plastic (73)