900 Litre GRAF Sapphire Underground Pit

SKU: 121202

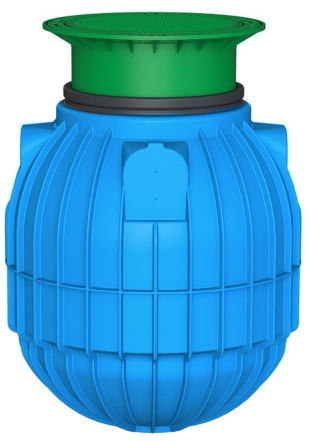

As with all of our range, our 900 Litre Vertical Sapphire Underground Tank by GRAF has been finite element analysis tested by a qualified engineer and designed to meet and exceed Australian Standard 1546.1 These tanks are widely used for sewage pump stations, lift stations, storm water pump systems and rainwater holding tanks. Manufactured from quality polyethylene and currently available in blue (as pictured).

Holding tanks are used to temporarily store wastewater before being pumped out, mainly found in remote areas without access to a sewer line. The Sapphire holding tank is ideal solution for volumes up to 1,500 litres.

Specifications

- Product Code: 121202

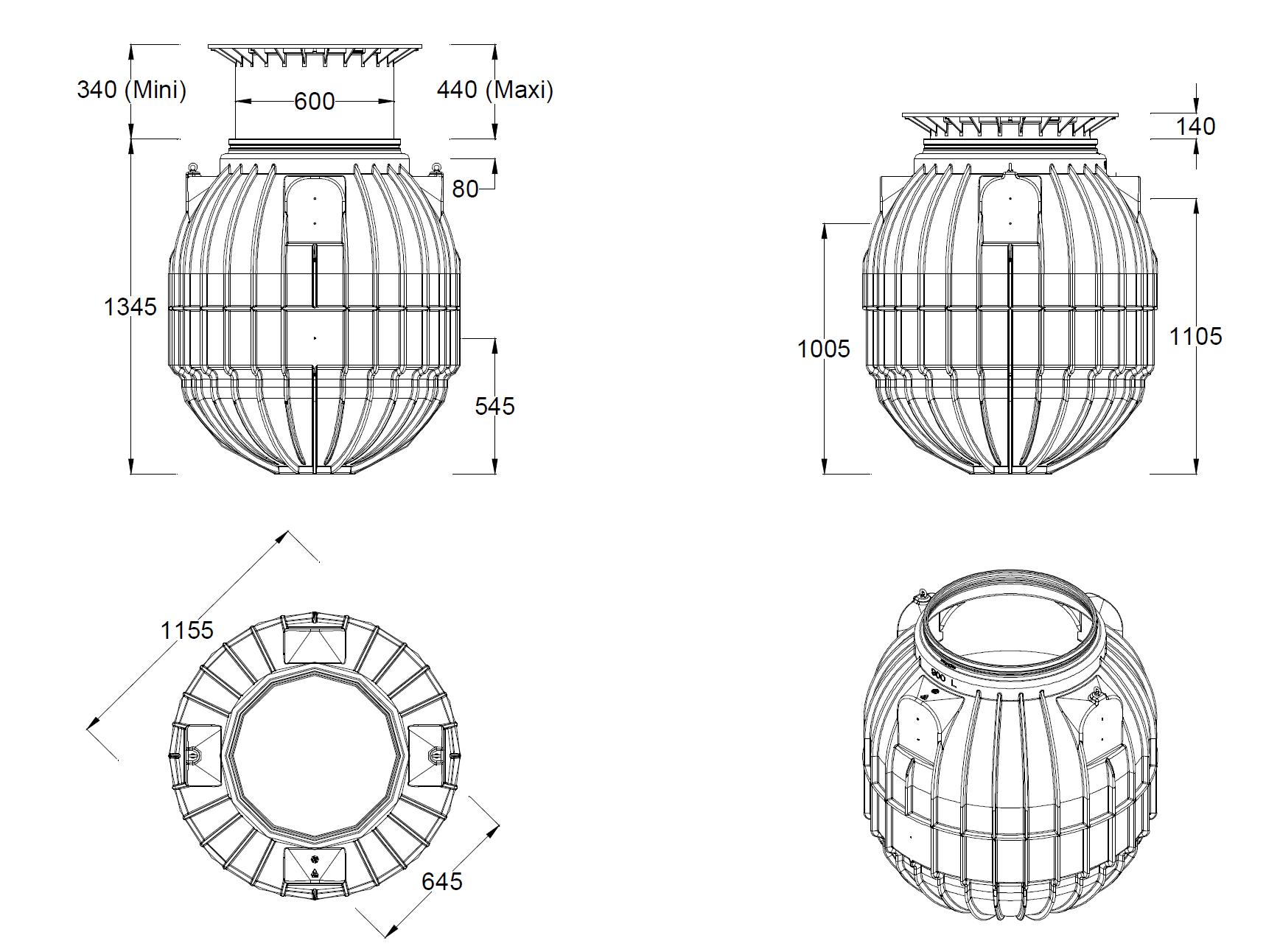

- Diameter: 1155mm

- Height: 1345mm

- 900 Litre Capacity (237.8 Gallons)

- Weight: 175KG

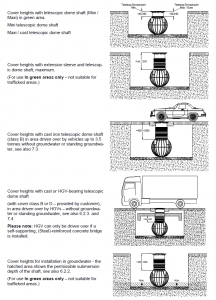

- Available with polyethylene pedestrian duty access cover/lid OR Class B cast iron lid

Features

- Numerous connection options for easy installation DN 100 / DN 150

- Telescopic / inclinable dome shaft for easy alignment with the connection lines

- Easy to transport thanks to its low weight

- With crane lugs for easy handling and placement in the excavation

- Including seal for easy assembly of the telescopic dome shaft

- Sealed to the surface of the terrain

- Groundwater stable 900L up to a height of 43 cm from the tank bottom and 1200L up to a height of 55 cm from the tank bottom

- Required earth cover (mm) : min 300 – max 600

- Unique stability and precise fit of the components

- 15 Year Warranty

- FEA tested by a qualified engineer and designed to meet and exceed the requirements of AS1546.1

- Manufactured from polyethylene

- Suitable for handling sewage, stormwater, trade waste

- Available in blue colour

Installation

Technical Data

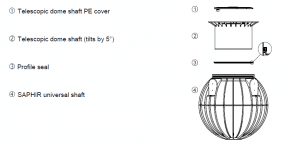

Structure of Shaft

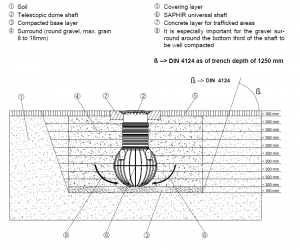

Installation & Assembly

6.1 Foundation

The following criteria must be verified prior to installation:

· The structural suitability of the soil in accordance with DIN 18196

· Maximum groundwater levels / drainage of the subsoil

· Types of loading present, e.g. traffic load

Please note: HGV can only be driven over if a self-supporting, steel-reinforced concrete bridge is installed! A soil survey should be requested from the local building authority to determine the physical properties of the soil.

6.2 Trench

To ensure that sufficient working space is available, the base area of the trench must exceed the shaft dimensions by over 300 mm on all sides. The distance from fixed structures must be at least 1000 mm.

Please note: If the trench depth is greater than 1250 mm, an embankment should be built in accordance with DIN 4124. The foundation must be horizontal and even and must offer sufficient load-bearing capacity.

The trench must be deep enough that the maximum earth cover above the shaft (see 3 – Installation conditions) is not exceeded. For the system to be usable all year round, the shaft and water-carrying parts

must be installed in a frost-free zone. The frost-free depth is usually around 600 mm – 800 mm; for accurate information, please contact the responsible authority. The substructure is made from a layer of compacted round gravel (grain 8/16, approx. 100 mm – 150 mm thick).

6.2.1 Positioning on a slope, embankment etc.

If the shaft is installed in immediate proximity (less than 5 m) to a slope, mound or embankment, a statically calculated supporting wall must be constructed to bear the pressure of the soil. The wall must exceed the shaft dimensions by at least 500 mm in all directions and must be at least 1000 mm away from the shaft.

6.2.2 Groundwater and cohesive (non-water-permeable) soils (e.g. loam)

If it is likely that the shafts will be submerged deeper in groundwater than indicated in the table below, sufficient drainage must be provided (for max. submersion depths and required earth cover, see table). In cohesive, non-water-permeable soils we recommend installing drainage (e.g. ring drainage) for seepage water (not below driven-on surfaces).

SAPHIR universal shaft: 900 litre

Max. submersion depth: 430 mm

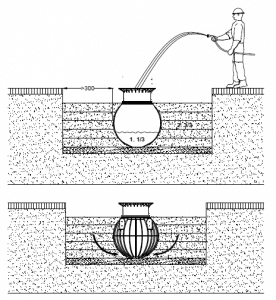

Required earth cover (mm): min. 300 – max. 600

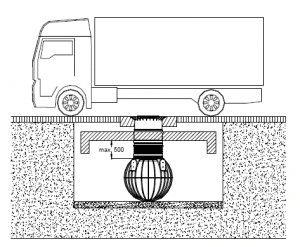

6.2.3 Installation below HGV-bearing surfaces

The shaft can only be driven over with HGV in conjunction with a self-supporting, iron-reinforced concrete bridge. To ensure that no additional forces or effects of HGV-bearing are transferred to the shafts, the dimensions and strength of the concrete bridge must be statically calculated.

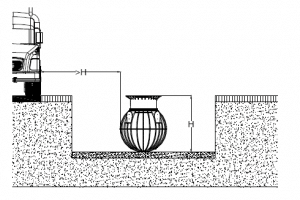

6.2.4 Installation next to driven-on surfaces

If the shafts are installed next to roadways used by heavy vehicles weighing over 3,5 t, the minimum distance from these surfaces must be at least the depth of the trench.

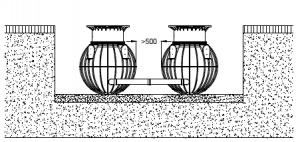

6.2.5 Connecting multiple shafts

Two or more shafts can be connected by means of drilling a hole in each tank and installing, Garantia special seals and 110mm underground pipe (pro-vided by the customer). The openings must only be drilled with the

Garantia special core drill and to the appropriate size. En-sure that the distance between the shafts is at least 500 mm. The pipes must extend at least 200 mm into the shafts.

6.2.6 Insertion and filling

The shafts should be carefully lowered into the excavation avoiding any sudden jolts. The shaft must be filled 1/3 full of water before commencing the back filling. The back fill should be carried out using 8 to 16mm single sized gravel

and compacted in 30cm (max.) layers until the top of the shaft is reached. The individual layers and the lower zone of the shafts must be well compacted (with a hand tamper). Be careful to avoid damaging the shafts when compacting the gravel. Mechanical compression machines must never be used. The trench surround must be at least 300 mm wide.

Please note: It is especially important for the filling in the bottom third of the shaft to be well compacted

Inspection & Maintenance

The entire system must be checked for tightness, cleanliness and stability at least once every three

months.

The entire system should be maintained approximately every 5 years. All parts should be cleaned and

their function checked. For maintenance, proceed as follows:

· Fully empty shaft

· Clean surfaces and built-in parts with water

· Remove all dirt and contamination from the shaft

· Check that all built-in parts are securely mounted

Please note: During every maintenance the outlet must be checked and flushed if necessary.

GRAF rainwater tank delivery zone

Our 900 Litre GRAF Sapphire Underground Pits are available for delivery within VIC, S.A & NSW – standard lead time is approx one week. Please feel free to give our team a call on 03 8795 7715 today for an obligation free quote.