Davey DT37G Submersible Grinder Pump 415V

SKU: DT37G

Submersible pump consisting of a solids handling grinder inlet with a high head open impeller to pump waste water containing soft solids in suspension.

APPLICATIONS

• Grey & Black Water Pumping

• Sump Emptying

• Septic effluent & sewage disposal

• Pumping of waste water with soft solids in suspension

DESIGN FEATURES

PUMP

- Heavy duty shredding and grinding ring

at inlet. - Centrifugal design, open impeller.

- Double Mechanical shaft seal in oil bath.

- Hard faced Silicon Carbide / Ceramic seal on pump side.

- Sand slinger lip seal for added protection.

- O-ring casing sealing.

- Corrosive resistant stainless steel and quality heavy duty powder coated cast

iron pump parts. - Seal sensor leads fitted for easy connection to a protection relay to enable timely repairs prior to motor

damage. - Not fitted to D75G/GA or

DT08G models.

MOTOR

- 2 pole, 2900rpm 50Hz 240 volt single phase or 415 volt three phase.

- Submersible with IPx8 enclosure.

- 10 metre HO7RN-F oil resistant power lead and seal sensor lead fitted with bared wire lead ends for easy connection to power supply terminations.

- Class E insulation.

- Protected against both high operating temperatures and high current by a built in automatically resetting thermal overload.

OPERATING LIMITS

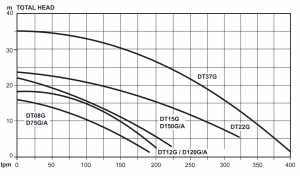

Capacities 290 lpm

Head to 38m

Max. submergence 25m

Max. operating temperature 50o

C

Suitable Fluids

Sewage or “Grey Water” of neutral

pH containing up to 20% soft

organic solids (some wear should be

expected while pumping hard solids

in suspension).

BENEFITS

Able to pump soft organic solids, sanitary products, thin rubber products and even some textiles in suspension, by shredding to a slurry

• Open impeller prevents blockage of the pump by small solids in the slurry

• High heads and small solids allow connection to small discharge pipe systems, especially suited to pumping waste water to pressure sewer mains

• Silent operation

• Quick and easy installation

• Hose tail supplied with every pump

• Low maintenance

• Fully repairable

• Mounting feet with rubber cushions fitted for a firm and stable positioning during installation and operation for D75G/GA, DT08G, D120G/A, D150G/A, DT12G & DT15G.

• Adaptable to slide rails

ACCESSORIES

These optional accessories are available:

• Slide rail kit – P/No SR50

• Seal Sensor relay, allows connection

to contactor warning system – Part

No. 49076

• Auto float switches are fitted to

D75GA, D120GA & D150GA models

• Separate automatic control panels

available for single or multiple pump

installations.

MATERIALS OF CONSTRUCTION

Impeller : Cast iron – FC200

Shredding ring : High Chromium steel

Grinding ring : High Chromium steel

Pump casing : Cast iron – FC200

Outlet : Cast iron – FC200

Shaft seal – pump side – Silicon carbide/ceramic

– motor side – Carbon/ceramic. Mechanical Seals in captive oil bath and oil seal

Shaft seal elastomer : Nitrile rubber

Pump shaft : 304 stainless steel

Orings : Nitrile rubber

Motor shell : 304 stainless steel

Handle : 304 stainless steel

Fasteners : 304 stainless steel

Float & power supply leads : HO7RN-F oil resistant

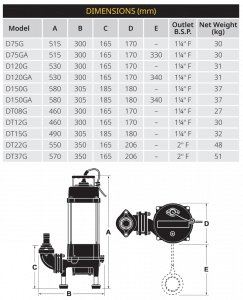

Pump Weight: 52Kg

ELECTRICAL DATA

Electrical lead: 10m

Phase: Three

Volts: 380-415

kW (nameplate): 3.7

Amps – FL: 8.5

Insulation E class

INSTALLATION & PRIMING

- Use a rope to position and retrieve the pump. Do not lower or retrieve

the pump using the power lead as this may damage the cable entry

seals, causing water leaks and unsafe operation. - Do not use this product for recirculating or filtering swimming pools,

spas, etc. While these pumps are built to high safety standards, they

are not approved for installations where people will be in the water

while they are operating. - Do not pump abrasive materials. Sand and grit in the water being

pumped will accelerate wear, causing shortened pump life. - Make room for the float switch to operate. Automatic models have a

float switch to turn them on when the water level rises and turn them

off again when it has been pumped down to the safe operating level of

the pump. If the float switch is not free to rise and fall, correct pump

operation may not be possible. - Don’t run your pump dry. Non-automatic models must be switched off

manually or by way of an external float/level switch when the water

level is reduced to the top of the pump housing.