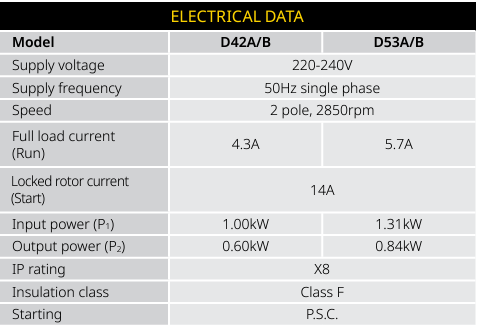

Davey D42A/B20 High Pressure Drainage Pump 240V

SKU: D42a/B20

FEATURES & BENEFITS

Davey Sump Pumps are used to remove water that has accumulated in a sump or pit, as well as emptying swimming pools and removing flood water from buildings etc. Davey Sump Pumps are used where there is flooding and to solve water entry in basements where the water table is above the foundation. Has a 20 meter Lead.

Double mechanical seal, one in oil bath on motor and extra mechanical seal on pump

• Superior reliability

• Long service life

Corrosion resistant 304 stainless steel shaft, motor shell and fasteners

• Long service life

Cast 316 stainless steel motor caps and super tough engineered thermo plastic pump casing

• Outstanding corrosion resistance

• Long life

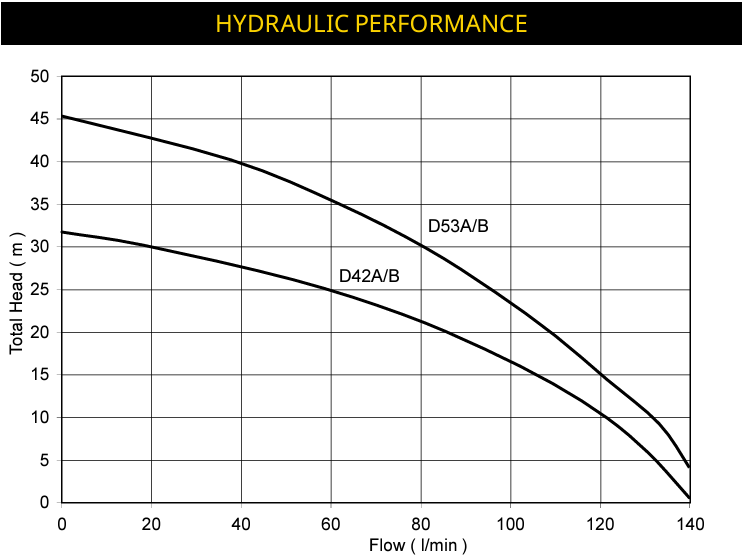

Centrifugal multistage 2 and 3 impeller designs

• Higher pressures and increased efficiency

Closed vane impellers with long engagement “D” drives

• Positive operation

• Long service life

Patented independently floating neck rings

• Outstanding pump performance

• Long pump life

Corrosion resistant hard wearing polycarbonate impellers

• Long service life

Corrosion resistant stainless steel fine mesh suction strainer with large surface area

• Prevents blockages of the pump by solids

In-built automatic thermal overload

• Protects the motor in the event of blockage or voltage supply problems

HO7RNF oil resistant leads, 10 metres long with 3 pin power plug

• Easy to connect to power supply

• Longer life in dirty water

APPLICATION

Ideal for non-potable rainwater applications, lawn and garden irrigation, sump emptying to higher heads, treated effluent disposal and water transfer from wells.

INSTALLATION AND PRIMING

INSTALLATION AND PRIMING

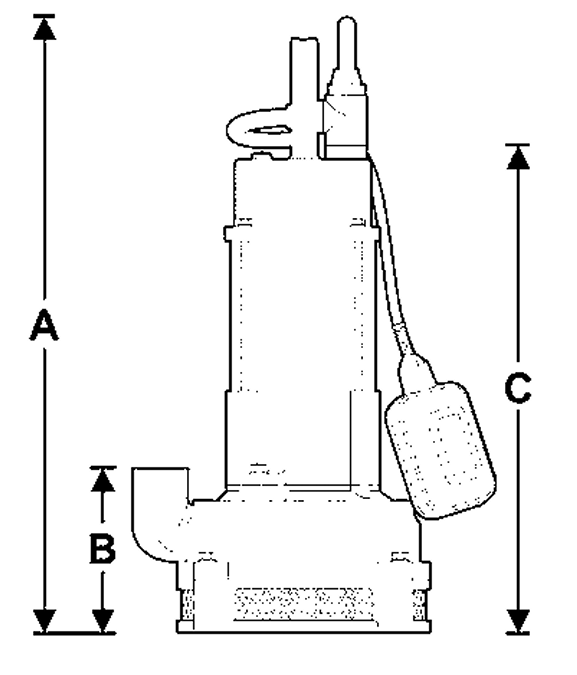

Use a rope to position and retrieve the pump. Do not lower or retrieve the pump using the power lead as this may damage the cable entry seals, causing water leaks and unsafe operation. Do not use this product for recirculating or filtering swimming pools, spas, etc. While these pumps are built to high safety standards, they are not approved for installations where people will be in the water while they are operating. Do not pump abrasive materials. Sand and grit in the water being pumped will accelerate wear, causing shortened pump life. Keep your pump clean, particularly in situations where lint, hair or fibrous materials may get bound around the pump shaft. Regular inspection and cleaning will extend pump life. Make room for the float switch to operate. Automatic models have a float switch to turn them on when the water level rises and turn them off again when it has been pumped down to the safe operating level of the pump. If the float switch is not free to rise and fall, correct pump operation may not be possible. Do not run your pump dry. Non-automatic models must be switched off manually or by way of an external float/level switch when the water level is reduced to the top of the pump housing.